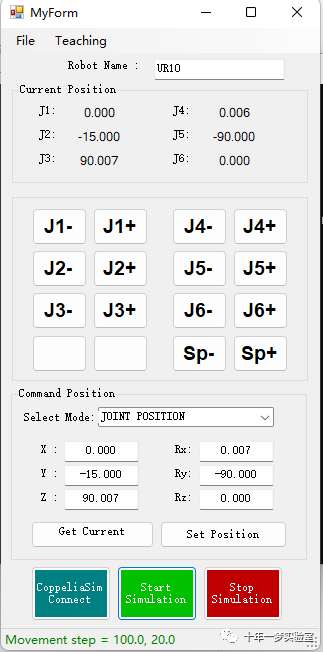

C++示教器

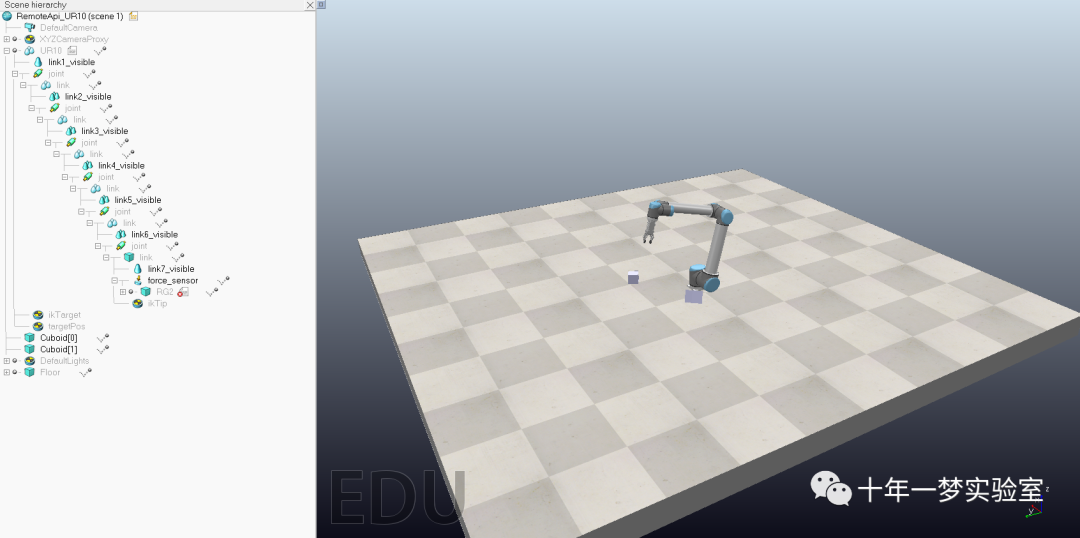

场景截图

视频演示

笔记:

一、用于 VS 2022 .NET 框架的 C++ Windows 窗体

通过用 C++ 编写的 Windows 窗体项目扩展 Visual Studio 2022 。此类项目创建的应用程序具有图形用户界面。它们基于 .NET Framework。您可以使用所有常见的 Windows 控件,如按钮、菜单、文本框等。

与传统 C++ 程序的主要区别在于,它不是使用控制台进行用户交互

cout << "Hello world" << endl;

您可以使用 Windows 控件,例如 TextBox

textBox1->AppendText("Hello World");

安装扩展 https://marketplace.visualstudio.com/items?itemName=RichardKaiser.cppclrwinf

创建项目时选择CppCLR_WinFormsProject

二、coppeliasim类是对remoteApi的封装,可以操作机器人、获取传感器数据.通过调用脚本函数进行任何可能的操作。

.h文件:

#pragma once

/*

NON_MATLAB_PARSING

MAX_EXT_API_CONNECTIONS=255

_CRT_SECURE_NO_WARNINGS

DO_NOT_USE_SHARED_MEMORY

*/

#include <stdlib.h>

#include <iostream>

#include <windows.h>

#include <stdio.h>

#include <process.h>

#include <fstream>

//#include <msclr\marshal_cppstd.h>

extern "C" {

#include "extApi.h"

//#include "simConst.h"

}

using namespace std;

#define RAD_TO_DEG (180/3.141592)

#define DEG_TO_RAD (3.141592/180)

//检索全局句柄 Retrieve global handle;

class CoppeliaSim {

public:

bool connected;//连接状态

int clientID;//客户端id

public:

bool connect(int port);//连接

void disconnect(int clientID);//断开连接

void startSimulation();//开始仿真

void stopSimulation();//停止仿真

};

//类:机器人 Class Robot

class CoppeliaRobot: public CoppeliaSim{

public:

void init(string robot_name);//初始化:机器人名称

void setPosition(float pos[6], bool wait);//设置位置

void setPosition(float x, float y, float z, float w, float p, float r, bool wait);//设置tcp位置 wait

void setPosition(float x, float y, float z, float w, float p, float r);//设置tcp位置

void setJointPosition(float joint[6], bool wait);//设置关节位置

void setJointPosition(float J1, float J2, float J3, float J4, float J5, float J6);//设置所有关节位置

void setJointPosition(int num, float tetha); // 设置单关节位置 Set single joint position

void setPosition2(float pos[6]); //直接设定物体位置(无速度控制) Direct set object position (no speed control)

void readCurrentJointPos(float joint_pos[6]);//读取当前关节位置

void readObjectPosition(string object_name, float current_pos[6]);//读取对象位置

void enableIk(bool enable);//启用IK

bool isMoving();//移动中

void setSpeed(float vel, float ang_vel);//设置速度

void gripperCatch();//夹爪抓取

void gripperRelease();//夹爪释放

void readPosition(float pos[6]);//读取tcp位置

void readForce(float force[6]);//读取六维力

void getObjectMatrix(float M[4][4]);//获取对象位姿矩阵

public:

int joint_handle[6];//机器人6个关节句柄

int forceSensor_handle;//力传感器句柄

simxChar * script_name;//脚本名称

string scriptName;//脚本名

//Ik Handle IK句柄

int ikTargetHandle;//ik目标句柄

int ikTipHandle;//ik tip句柄

int robotHandle;//机器人句柄

int moving;//移动状态

int ftHandle;//力传感器句柄

int targetPosHandle;//目标位置句柄

float __force[3];//三维力

float __torque[3];//三维力矩

float __pos[3];//位置

float __rot[3];//姿态

int __cnt; //输出位置的数量

float* __position;//位置指针

float* __jointpos;//关节位置指针

simxUChar state;//力传感器状态

};

//类:力传感器 Class Force Sensor

class CoppeliaForce{

public:

void init(int clientID, simxChar * obj_name);//初始化力传感器:获取其句柄

void read(float force[6]);//读取六维力

private:

int forceHandle;//力传感器句柄

int clientID;//客户端id

};.cpp文件:

#include "coppeliasim.h"

#include <windows.h>

// Connect to coppelia sim, defaulf port: 19997

/////////////////////////////////////////////////////////////////////

bool CoppeliaSim::connect(int port)

{

if (!connected) {

simxFinish(-1);//最后一个要调用的函数

this->clientID = simxStart((simxChar*)"127.0.0.1", port, true, true, 2000, 5);//连接服务器

if (this->clientID != -1) {

this->connected = true;

printf("> CoppeliaSIM connection success! Client ID : %d \n", clientID);

// Start simulation:

//simxStartSimulation(clientID, simx_opmode_oneshot_wait);

return true;

}

else {

printf("> Simxstart failed!!! \n");

}

}

else {

printf("> CoppeliaSim already connected. Please disconnect first. \n");//已经连接

}

return false;

}

////////////////////////////////////////////////////////////////////

//断开与CoppeliaSim服务器的连接

void CoppeliaSim::disconnect(int clientID)

{

this->connected = false;

simxFinish(clientID);

}

// 开始仿真Start Simulation

void CoppeliaSim::startSimulation() {

simxStartSimulation(clientID, simx_opmode_blocking);

}

//停止仿真

void CoppeliaSim::stopSimulation() {

simxStopSimulation(clientID, simx_opmode_blocking);

}

// 力传感器初始化,获取其句柄 Force Sensor

void CoppeliaForce::init(int clientID, simxChar * obj_name)

{

this->clientID = clientID;

simxGetObjectHandle(this->clientID, obj_name, &forceHandle, simx_opmode_oneshot_wait);//获取力传感器句柄

printf("__INFO___: Coppeliasim force sensor handle ID : %d \n", forceHandle);

}

//读取六维力:力和力矩

void CoppeliaForce::read(float force[6])

{

simxUChar state;//状态

float _torque[3] = {0 ,0 ,0 };//三维力矩

float _force[3] = {0, 0, 0,};//三维力

simxReadForceSensor(this->clientID, forceHandle, &state, _force, _torque, simx_opmode_continuous);//读取力传感器状态

for (int i = 0; i < 3; i++) {

force[i] = _force[i];

}

for (int i = 0; i < 3; i++) {

force[i + 3] = _torque[i];

}

// printf("Force Data: %.3f %.3f %.3f \n", force[0], force[1], force[2]);

}

//机器人类 Robot Class

///////////////////////////////////////////////////////////////////

//启用IK

void CoppeliaRobot::enableIk(bool enable)

{

int dataSend;//要发送的数据

if (enable) dataSend = 1;//启用ik,发送1

else dataSend = 0;//不启用ik,发送0

//调用脚本函数

int result = simxCallScriptFunction(

clientID,

script_name, // 关联对象脚本的名称the name of the associated obejct script

sim_scripttype_childscript, // 脚本的句柄 the handle of the script

"enableIk", // 函数名称 Function name

1, &dataSend, //输入的int数量,输入的int指针 inIntCnt, inInt

0, NULL, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

NULL, NULL, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_oneshot);//单次模式

}

// Robot initialization: retreive some handles:

//////////////////////////////////////////////////////////////////////

//机器人初始化:检索一些句柄:

void CoppeliaRobot::init(string robot_name) {

string temp("/" + robot_name);

scriptName = temp;

string target_obj_name("./" + robot_name + "/ikTarget");//ik目标名称 字符串

string tip_obj_name ("./" + robot_name + "/ikTip");//iktip名称 字符串

string ft_obj_name ("./" + robot_name + "/force_sensor");//力传感器名称 字符串

string targetPos_obj_name("./" + robot_name + "/targetPos");//目标位置对象名称

simxGetObjectHandle(clientID, robot_name.c_str(), &robotHandle, simx_opmode_blocking);//获取机器人句柄

simxGetObjectHandle(clientID, target_obj_name.c_str(), &ikTargetHandle, simx_opmode_blocking);//获取目标对象句柄

simxGetObjectHandle(clientID, tip_obj_name.c_str(), &ikTipHandle, simx_opmode_blocking);//获取tip句柄

simxGetObjectHandle(clientID, ft_obj_name.c_str(), &ftHandle, simx_opmode_blocking);//获取力传感器句柄

simxGetObjectHandle(clientID, targetPos_obj_name.c_str(), &targetPosHandle, simx_opmode_blocking);//获取目标位置句柄

cout << "\n\nSimulation properties:" << endl;

cout << "Robot Handle: " << robotHandle << endl;

cout << "ikTarget : " << ikTargetHandle << endl;

cout << "ikTip : " << ikTipHandle << endl;

cout << "Force Sensor: " << ftHandle << endl;

//启动流数据事务:Start Stream data routine:

simxReadForceSensor(clientID, ftHandle, &state, __force, __torque, simx_opmode_streaming);//获取力传感器数据

simxGetIntegerSignal(clientID, "moving_status", &moving, simx_opmode_streaming);//获取整型信号 moving_status。

//simxGetObjectPosition(clientID, ikTipHandle, robotHandle, __pos, simx_opmode_streaming);

//simxGetObjectOrientation(clientID, ikTipHandle, robotHandle, __rot, simx_opmode_streaming);

// 位置数据流 Stream position data:

simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script 关联的对象脚本名

sim_scripttype_childscript, // the handle of the script 脚本类型:子脚本

"remoteApi_getPosition", // Function name 调用脚本的函数名remoteApi_getPosition

0, NULL, // inIntCnt, inInt

0, NULL, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

&__cnt, &__position, // outFloatCnt, outFloat //浮点数量,浮点数指针

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_streaming);//流操作模式

// 关节位置数据 Stream joint position data:

simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"remoteApi_getJointPosition", // Function name 脚本的获取关节位置函数

0, NULL, // inIntCnt, inInt

0, NULL, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

&__cnt, &__position, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_streaming);

}

//读取力传感器数据

void CoppeliaRobot::readForce(float force[6]) {

simxReadForceSensor(clientID, ftHandle, &state, __force, __torque, simx_opmode_buffer);

for (int i = 0; i < 3; i++) {

force[i] = __force[i];

force[i + 3] = __torque[i];

}

}

// 设置机械臂位置Set robot arm position:

// ////////////////////////////////////////////////////////////////////

void CoppeliaRobot::setPosition(float pos[6], bool wait)

{

setPosition(pos[0], pos[1], pos[2], pos[3], pos[4], pos[5]);

if (wait){

while (isMoving());

}

}

//设置位置

void CoppeliaRobot::setPosition(float x, float y, float z, float w, float p, float r, bool wait)

{

setPosition(x, y, z, w, p, r);

if (wait) {

while (isMoving());

}

}

//设置tcp位置

void CoppeliaRobot::setPosition(float x, float y, float z, float w, float p, float r)

{

//enableIk(true); //启用IK模式 Enable IK mode

float pos[6];

pos[0] = x / 1000; // meter

pos[1] = y / 1000; // meter

pos[2] = z / 1000; // meter

pos[3] = w * DEG_TO_RAD; // rad

pos[4] = p * DEG_TO_RAD; // rad

pos[5] = r * DEG_TO_RAD; // rad

//调用脚本函数

int result = simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"remoteApi_movePosition", // Function name 移动位置函数remoteApi_movePosition

0, NULL, // inIntCnt, inInt

6, pos, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

NULL, NULL, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_oneshot);//单次模式

}

//设置机器人关节位置 Set Robot Joint Position:

///////////////////////////////////////////////////////////////////////////

void CoppeliaRobot::setJointPosition(float joint[6], bool wait) {

setJointPosition(joint[0], joint[1], joint[2], joint[3], joint[4], joint[5]);

if(wait) while (isMoving()); // Wait moving

}

void CoppeliaRobot::setJointPosition(float J1, float J2, float J3, float J4, float J5, float J6)

{

//enableIk(false); // Enable Joint MODE

float joint[6];

joint[0] = J1 * (DEG_TO_RAD);

joint[1] = J2 * (DEG_TO_RAD);

joint[2] = J3 * (DEG_TO_RAD);

joint[3] = J4 * (DEG_TO_RAD);

joint[4] = J5 * (DEG_TO_RAD);

joint[5] = J6 * (DEG_TO_RAD);

int result = simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"remoteApi_moveJointPosition", // Function name

0, NULL, // inIntCnt, inInt

6, joint, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

NULL, NULL, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_oneshot);

}

//设置关节位置:调用脚本函数moveSingleJointPosition

void CoppeliaRobot::setJointPosition(int num, float tetha)

{

enableIk(false); // Enable Joint Mode

float jointAngle = tetha * DEG_TO_RAD;

int result = simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"moveSingleJointPosition", // Function name

1, &num, // inIntCnt, inInt

1, &jointAngle, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

NULL, NULL, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_oneshot_wait);

while (isMoving());//等待到位?

}

//读取当前机器人关节位置 调用脚本函数:remoteApi_getJointPosition Read Current Robot Joint Position:

void CoppeliaRobot::readCurrentJointPos(float joint_pos[6])

{

int cnt;//6个关节

float *jointData;//关节数据指针

int* inData = nullptr;//

int result = simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"remoteApi_getJointPosition", // Function name

0, NULL, // inIntCnt, inInt

0, NULL, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

&cnt, &jointData, // outFloatCnt, outFloat 数量,关节数据

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_buffer);

if (jointData==NULL)

{

return;

}

try

{

for (int i = 0; i < 6; i++) {

joint_pos[i] = jointData[i] * RAD_TO_DEG;

}

}

catch (const std::exception& e)

{

//MessageBoxA(NULL,e.what(), "Warn", MB_OK); //winuser.h https://docs.microsoft.com/en-us/windows/win32/api/winuser/nf-winuser-messageboxa

}

}

// Get robot moving status. Return TRUE if the robot is moving and

// return FALSE is robot is stop.

// 获取机器人移动状态。如果机器人正在移动并且返回 TRUE

// 返回 FALSE 是机器人停止。

bool CoppeliaRobot::isMoving() {

Sleep(50);

simxGetIntegerSignal(clientID, "moving_status", &moving, simx_opmode_buffer);//获取移动状态

if (moving) return true;//1:移动中

else return false;//0:未移动

}

//手臂机器人手抓 抓 Arm Robot Gripper Catch

void CoppeliaRobot::gripperCatch()

{

int state = 0;//输入夹爪状态 0

int result = simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"remoteApi_setGripper", // Function name

1, &state, // inIntCnt, inInt

0, NULL, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

NULL, NULL, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_oneshot);

}

//释放夹爪 Arm Robot Gripper Gripper Release

void CoppeliaRobot::gripperRelease()

{

int state = 1;//释放夹爪:1

int result = simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"remoteApi_setGripper", // Function name//调用脚本函数:remoteApi_setGripper

1, &state, // inIntCnt, inInt

0, NULL, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

NULL, NULL, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_oneshot);//单次调用模式

}

// Get Robot Tip Homogeneous Matrix:

/////////////////////////////////////////////////////////////////////////////////

//获取tip位姿矩阵

void CoppeliaRobot::getObjectMatrix(float M[4][4])

{

int cnt;//12

float *pData;//位姿矩阵数据

int result = simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"getObjectMatrix", // Function name //获取tip位姿矩阵

0, NULL, // inIntCnt, inInt

0, NULL, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

&cnt, &pData, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_oneshot_wait);

M[0][0] = pData[0];

M[0][1] = pData[1];

M[0][2] = pData[2];

M[0][3] = pData[3];

M[1][0] = pData[4];

M[1][1] = pData[5];

M[1][2] = pData[6];

M[1][3] = pData[7];

M[2][0] = pData[8];

M[2][1] = pData[9];

M[2][2] = pData[10];

M[2][3] = pData[11];

M[3][0] = 0;

M[3][1] = 0;

M[3][2] = 0;

M[3][3] = 1;

}

// 读取当前机器人tip位置 Read Current Robot Tip Position

/////////////////////////////////////////////////////////////////////////////////

void CoppeliaRobot::readPosition(float currentPos[6])

{

/*

simxGetObjectPosition(clientID, ikTipHandle, robotHandle, __pos, simx_opmode_buffer);

simxGetObjectOrientation(clientID, ikTipHandle, robotHandle, __rot, simx_opmode_buffer);

currentPos[0] = __pos[0] * 1000; //mm

currentPos[1] = __pos[1] * 1000; //mm

currentPos[2] = __pos[2] * 1000; //mm

currentPos[3] = __rot[0] * RAD_TO_DEG;

currentPos[4] = __rot[1] * RAD_TO_DEG;

currentPos[5] = __rot[2] * RAD_TO_DEG;

*/

simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"remoteApi_getPosition", // Function name 脚本函数:获取tip位置 remoteApi_getPosition

0, NULL, // inIntCnt, inInt

0, NULL, // inFloatCnt, inFloat

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

&__cnt, &__position, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_buffer);

//位姿数据 转换为合适单位

if (__position != nullptr) {

currentPos[0] = __position[0] * 1000; //mm

currentPos[1] = __position[1] * 1000; //mm

currentPos[2] = __position[2] * 1000; //mm

currentPos[3] = __position[3] * RAD_TO_DEG;

currentPos[4] = __position[4] * RAD_TO_DEG;

currentPos[5] = __position[5] * RAD_TO_DEG;

}

}

//读取对象位置

void CoppeliaRobot::readObjectPosition(string object_name, float currentPos[6]) {

int object_handle;//对象句柄

float position[3], orientation[3];//位置,姿态向量

simxGetObjectHandle(clientID, object_name.c_str(), &object_handle, simx_opmode_oneshot_wait);//获取对象句柄

simxGetObjectPosition(clientID, object_handle, robotHandle, position, simx_opmode_oneshot_wait);//获取对象位置

simxGetObjectOrientation(clientID, object_handle, robotHandle, orientation, simx_opmode_oneshot_wait);//获取对象姿态

currentPos[0] = position[0] * 1000; //mm

currentPos[1] = position[1] * 1000; //mm

currentPos[2] = position[2] * 1000; //mm

currentPos[3] = orientation[0] * RAD_TO_DEG;

currentPos[4] = orientation[1] * RAD_TO_DEG;

currentPos[5] = orientation[2] * RAD_TO_DEG;

}

// 直接设置机器人位置和方向(无速度控制) 需IK模式 Directly set the robot position and orientation (no speed control)

void CoppeliaRobot::setPosition2(float pos[6])

{

float position[3], orientation[3];

for (int i = 0; i < 3; i++) {

position[i] = pos[i] / 1000; // mm

orientation[i] = pos[i + 3] * DEG_TO_RAD;

}

simxSetObjectPosition(clientID, ikTargetHandle, robotHandle, position, simx_opmode_oneshot_wait);//设置机器人位置

simxSetObjectOrientation(clientID, ikTargetHandle, robotHandle, orientation, simx_opmode_oneshot_wait);//设置机器人方向

}

// 设置机器人速度Set Robot Speed : 0 - 100

///////////////////////////////////////////////////////////////////////

void CoppeliaRobot::setSpeed(float vel, float ang_vel)

{

float lin_vel = vel / 1000; //线速度

float rad_vel = ang_vel * DEG_TO_RAD; //角速度

float vel_data[2] = {lin_vel, rad_vel};//速度数组

//调用脚本函数remoteApi_setSpeed

int result = simxCallScriptFunction(

clientID,

scriptName.c_str(), // the name of the associated obejct script

sim_scripttype_childscript, // the handle of the script

"remoteApi_setSpeed", // Function name

0, NULL, // inIntCnt, inInt

2, vel_data, // inFloatCnt, inFloat 2个速度,线速度和角速度

0, NULL, // inStringCnt, inString

0, NULL, // inBufferSize, inBuffer

NULL, NULL, // outIntCnt, outInt

NULL, NULL, // outFloatCnt, outFloat

NULL, NULL, // outStringCnt, outString

NULL, NULL, // outBufferSize, outBuffer

simx_opmode_blocking);

}三、主窗体程序:读取关节位置、tip位置。连接、断开服务器;启动、停止仿真。单关节控制、tip位置控制。

#include "MyForm.h"

#include "TeachingForm.h"

#include "include/coppeliasim.h"

#include "variables.h"

#include <iostream>

#include <windows.h>

using namespace System;

using namespace System::Windows::Forms;

using namespace UI_Demo;

using namespace std;

CoppeliaSim mSim; //仿真器对象

CoppeliaRobot mRobot;//机器人对象

float posData[6];//

int mode = 0;// 0-IK 1-FK

int step_index = 0;

float pos_step_data[6] = { 1, 5, 10, 20, 50, 100};//位置步进数据

float ang_step_data[6] = { 0.5, 1, 2, 5, 10, 20};//角度步进数据

float pos_step = 10;

float ang_step = 0;

// 函数声明Prototype Function

void thread_read_data(void*);

// 初始化对话框 Initialization program

void MyForm::on_init() {

//设置定时器 Initialize timer:

timer1->Interval = 50;

timer1->Enabled = true;

cb_selectmode->SelectedIndex = mode;

_beginthread(thread_read_data, 0, NULL);//开启更新数据线程

label_status->Text = "Initialize program";//初始化程序

}

// 更新变量posData数据 线程 Thread for updating the data

void thread_read_data(void*) {

while (true) {

if (mode == 0) {//ikmode

mRobot.readPosition(posData);//读取tip位姿,得到posData[]

}

else {//关节模式

mRobot.readCurrentJointPos(posData);//读取关节位置 得到posData[]

}

Sleep(50);

}

}

//定时器函数:根据posData更新UI数据 Timer function: update the GUI information

void MyForm::on_timer() {

update_pos_data();//定时更新UI位置数据 tb_pos_x->Text = posData[0].ToString("N3");

}

//连接 端口19997

void MyForm::btn_connect() {

if (mSim.connect(19997)) {

label_status->Text = "Coppeliasim connection success...";

label_status->ForeColor = System::Drawing::Color::Green;

mSim.startSimulation();

mRobot.init("UR10");

}

}

//开始仿真

void MyForm::btn_start_sim() {

mSim.startSimulation();

}

//停止仿真

void MyForm::btn_stop_sim() {

mSim.stopSimulation();

}

//修改标签

void MyForm::change_label() {

mode = cb_selectmode->SelectedIndex;

if (mode == 0) {//IK模式

label_x->Text = "X:";

label_y->Text = "Y:";

label_z->Text = "Z:";

label_rx->Text = "Rx:";

label_ry->Text = "Ry:";

label_rz->Text = "Rz:";

btn_x_min->Text = "X-";

btn_x_plus->Text = "X+";

btn_y_min->Text = "Y-";

btn_y_plus->Text = "Y+";

btn_z_min->Text = "Z-";

btn_z_plus->Text = "Z+";

btn_rx_min->Text = "Rx-";

btn_rx_plus->Text = "Rx+";

btn_ry_min->Text = "Ry-";

btn_ry_plus->Text = "Ry+";

btn_rz_min->Text = "Rz-";

btn_rz_plus->Text = "Rz+";

}

else {//关节模式

label_x->Text = "J1:";

label_y->Text = "J2:";

label_z->Text = "J3:";

label_rx->Text = "J4:";

label_ry->Text = "J5:";

label_rz->Text = "J6:";

btn_x_min->Text = "J1-";

btn_x_plus->Text = "J1+";

btn_y_min->Text = "J2-";

btn_y_plus->Text = "J2+";

btn_z_min->Text = "J3-";

btn_z_plus->Text = "J3+";

btn_rx_min->Text = "J4-";

btn_rx_plus->Text = "J4+";

btn_ry_min->Text = "J5-";

btn_ry_plus->Text = "J5+";

btn_rz_min->Text = "J6-";

btn_rz_plus->Text = "J6+";

}

update_set_data();

}

void MyForm::update_pos_data() {

tb_pos_x->Text = posData[0].ToString("N3");

tb_pos_y->Text = posData[1].ToString("N3");

tb_pos_z->Text = posData[2].ToString("N3");

tb_pos_rx->Text = posData[3].ToString("N3");

tb_pos_ry->Text = posData[4].ToString("N3");

tb_pos_rz->Text = posData[5].ToString("N3");

}

//更新数据

void MyForm::update_set_data() {

float pos[6];

if (mode == 0) {

mRobot.readPosition(pos);//读取tip位姿

}

else {

mRobot.readCurrentJointPos(pos);//读取关节位置

}

tb_set_x->Text = pos[0].ToString("N3");//保留3位小数

tb_set_y->Text = pos[1].ToString("N3");

tb_set_z->Text = pos[2].ToString("N3");

tb_set_rx->Text = pos[3].ToString("N3");

tb_set_ry->Text = pos[4].ToString("N3");

tb_set_rz->Text = pos[5].ToString("N3");

}

//获取当前位置

void MyForm::btn_get_position() {

tb_set_x->Text = tb_pos_x->Text;

tb_set_y->Text = tb_pos_y->Text;

tb_set_z->Text = tb_pos_z->Text;

tb_set_rx->Text = tb_pos_rx->Text;

tb_set_ry->Text = tb_pos_ry->Text;

tb_set_rz->Text = tb_pos_rz->Text;

}

//设置机械臂位置

void MyForm::btn_set_position() {

float cmdPos[6];

cmdPos[0] = Convert::ToDouble(tb_set_x->Text);

cmdPos[1] = Convert::ToDouble(tb_set_y->Text);

cmdPos[2] = Convert::ToDouble(tb_set_z->Text);

cmdPos[3] = Convert::ToDouble(tb_set_rx->Text);

cmdPos[4] = Convert::ToDouble(tb_set_ry->Text);

cmdPos[5] = Convert::ToDouble(tb_set_rz->Text);

mRobot.setSpeed(30, 90);//设置速度:线速度、角速度

if (mode == 0) {

mRobot.setPosition(cmdPos, false);//设置tip位置

}

else {

mRobot.setJointPosition(cmdPos, false);//设置关节位置

}

}

//运动控制:单关节控制 或者 tip单维度控制

void MyForm::movement_control(int id) {

if (mode == 0) {//IK模式

float pos[6];

mRobot.readPosition(pos);

// x

if (id == 1) pos[0] -= pos_step;

else if (id == 2) pos[0] += pos_step;

// y

else if (id == 3) pos[1] -= pos_step;

else if (id == 4) pos[1] += pos_step;

// z

else if (id == 5) pos[2] -= pos_step;

else if (id == 6) pos[2] += pos_step;

// w

else if (id == 7) pos[3] -= ang_step;

else if (id == 8) pos[3] += ang_step;

// p

else if (id == 9) pos[4] -= ang_step;

else if (id == 10) pos[4] += ang_step;

// r

else if (id == 11) pos[5] -= ang_step;

else if (id == 12) pos[5] += ang_step;

mRobot.setPosition(pos, false);

}

else {//关节模式

float pos[6];

mRobot.readCurrentJointPos(pos);//读取当前关节位置

// x

if (id == 1) pos[0] -= ang_step;

else if (id == 2) pos[0] += ang_step;

// y

else if (id == 3) pos[1] -= ang_step;

else if (id == 4) pos[1] += ang_step;

// z

else if (id == 5) pos[2] -= ang_step;

else if (id == 6) pos[2] += ang_step;

// w

else if (id == 7) pos[3] -= ang_step;

else if (id == 8) pos[3] += ang_step;

// p

else if (id == 9) pos[4] -= ang_step;

else if (id == 10) pos[4] += ang_step;

// r

else if (id == 11) pos[5] -= ang_step;

else if (id == 12) pos[5] += ang_step;

mRobot.setJointPosition(pos, false);

}

}

//减小步进量

void MyForm::step_decrease() {

char str[128];

step_index--;

if (step_index < 0) step_index = 0;

pos_step = pos_step_data[step_index];

ang_step = ang_step_data[step_index];

sprintf(str,"Movement step = %.1f, %.1f", pos_step, ang_step);

label_status->Text = gcnew String(str);

}

//增加步进量

void MyForm::step_increase() {

char str[128];

step_index++;

if (step_index > 5) step_index = 5;//共6个步进模式

pos_step = pos_step_data[step_index];

ang_step = ang_step_data[step_index];

sprintf(str,"Movement step = %.1f, %.1f", pos_step, ang_step);

label_status->Text = gcnew String(str);

}

//显示示教窗口

void MyForm::show_teaching_form() {

TeachingForm ^ form = gcnew TeachingForm;//实例化示教窗口

form->Show();

}四、示教窗口:指令(集合)操作

#include "TeachingForm.h"

#include "variables.h" //外部数据定义

#include <msclr\marshal_cppstd.h>

using namespace System;

using namespace System::Windows::Forms;

using namespace UI_Demo;

using namespace std;

using namespace msclr::interop;

vector<record_t> recorded_pos;//指令集

//示教窗口初始化

void TeachingForm::on_init() {

char str[256];

record_t mPos;//一条指令数据

int size = recorded_pos.size();//指令集数量

//遍历所有指令

for (int i = 0; i < size; i++) {

mPos = recorded_pos[i];

sprintf(str, "[%d] %s = %.3f, %.3f, %.3f, %.3f, %.3f, %.3f",

mode, mPos.label.c_str(),

mPos.pos[0],

mPos.pos[1],

mPos.pos[2],

mPos.pos[3],

mPos.pos[4],

mPos.pos[5]

);

listBox1->Items->Add(gcnew String(str));//列表显示所有指令

}

}

//添加指令

void TeachingForm::btn_add() {

char str[256];

record_t mPos;

for(int i = 0; i < 6; i++)

mPos.pos[i] = posData[i];//当前位置数据

mPos.label = marshal_as<string>(textBox1->Text);//标签 :用户输入

if (mPos.label == "")

mPos.label = "recorded_pos";//默认标签

mPos.mode = mode;//指令模式

sprintf(str, "[%d] %s = %.3f, %.3f, %.3f, %.3f, %.3f, %.3f",

mode, mPos.label.c_str(),

mPos.pos[0],

mPos.pos[1],

mPos.pos[2],

mPos.pos[3],

mPos.pos[4],

mPos.pos[5]

);//指令字符串

printf(str);

listBox1->Items->Add(gcnew String(str));//显示

recorded_pos.push_back(mPos);//添加到指令集

}

//移除到选择的指令数据

void TeachingForm::btn_move() {

record_t mPos;

int index;

mRobot.setSpeed(30, 30);//设置速度

index = listBox1->SelectedIndex;//选择记录索引

mPos = recorded_pos[index];//指令数据

float cmdPos[6];

for (int i = 0; i < 6; i++)

cmdPos[i] = mPos.pos[i];//指令位置

if (mPos.mode == 0)

mRobot.setPosition(cmdPos, false);//移动tip位置

else

mRobot.setJointPosition(cmdPos, false);//移动关节位置

}

//删除

void TeachingForm::btn_delete() {

}五、全局变量variables.h

#pragma once

#include <iostream>

#include <vector>

#include "include/coppeliasim.h"

//该类定义了全局变量

using namespace std;

//一条记录:指令记录

typedef struct record_t {

int mode;//模式

float pos[6];//位置

string label;//标签

};

extern vector<record_t> recorded_pos;//指令集

extern float posData[6];//位置数组:tip位姿或者关节位置

extern int mode;//当前模式

extern CoppeliaSim mSim;//仿真器句柄

extern CoppeliaRobot mRobot;//机器人句柄六、Lua脚本函数:C++可以调用

-- ======================================================

-- RemoteApi Functions

-- ======================================================

-- Set Robot Speed --

function remoteApi_setSpeed(inInt,inFloat,inString,inBuffe)

local linear_vel=inFloat[1]

local angular_vel=inFloat[2]

local ikMaxVel={linear_vel, linear_vel, linear_vel, angular_vel}

local fkMaxVel={angular_vel, angular_vel, angular_vel, angular_vel, angular_vel, angular_vel}

print('Remote API -> Set robot speed = ', ikMaxVel)

ik_data.maxVel = ikMaxVel

fk_data.maxVel = fkMaxVel

end

-- Move Robot Position --

function remoteApi_movePosition(inInt,inFloat,inString,inBuffer)

targetPos={}

targetPos[1]=inFloat[1]

targetPos[2]=inFloat[2]

targetPos[3]=inFloat[3]

targetPos[4]=inFloat[4]

targetPos[5]=inFloat[5]

targetPos[6]=inFloat[6]

moveIkMode=true

end

-- Move Robot Joint Position --

function remoteApi_moveJointPosition(inInt,inFloat,inString,inBuffer)

targetJoint={}

for i=1,6,1 do

targetJoint[i] = inFloat[i]

end

moveJointMode=true

end

-- Get Object Position --

function remoteApi_getPosition()

--val = sim.getFloatSignal('forceX')

local pos=sim.getObjectPosition(simTip, simRobot)

local rot=sim.getObjectOrientation(simTip, simRobot)

local endpos = {pos[1],pos[2],pos[3],rot[1],rot[2],rot[3]}

return {},endpos,{},''

end

-- Get Object Joint Position --

function remoteApi_getJointPosition()

local jointPos={}

for i=1,6,1 do

jointPos[i]=sim.getJointPosition(simJoints[i])

end

return {},jointPos,{},''

end

-- Set Gripper --

function remoteApi_setGripper(state)

velocity=0.11

force=20

if state[1]==0 then

velocity=-velocity

end

local dat={}

dat.velocity=velocity

dat.force=force

sim.writeCustomDataBlock(simGripper,'activity',sim.packTable(dat))

end

-- ========================================================

-- Kinematic Functions

-- ========================================================

-- Inverse Kinematic --

function moveToPoseCallback(q,velocity,accel,auxData)

sim.setObjectPose(simTarget,-1,q)

simIK.applyIkEnvironmentToScene(auxData.ikEnv,auxData.ikGroup)

end

function moveToPose_viaIK(auxData, pose)

local pos = {pose[1], pose[2], pose[3]}

local ori = {pose[4], pose[5], pose[6]}

sim.setObjectPosition(simTargetPos, simRobot, pos)

sim.setObjectOrientation(simTargetPos, simRobot, ori)

local targetQ = sim.getObjectPose(simTargetPos,-1)

local currentQ = sim.getObjectPose(simTip,-1)

return sim.moveToPose(-1,currentQ,auxData.maxVel,auxData.maxAccel,auxData.maxJerk,targetQ,moveToPoseCallback,auxData,nil)

end

-- Forward Kinematic --

function moveToConfigCallback(config,velocity,accel,auxData)

for i=1,#auxData.joints,1 do

local jh=auxData.joints[i]

if sim.isDynamicallyEnabled(jh) then

sim.setJointTargetPosition(jh,config[i])

else

sim.setJointPosition(jh,config[i])

end

end

end

function moveToConfig_viaFK(auxData, goalConfig)

local startConfig={}

for i=1,#auxData.joints,1 do

startConfig[i]=sim.getJointPosition(auxData.joints[i])

end

sim.moveToConfig(-1,startConfig,nil,nil,auxData.maxVel,auxData.maxAccel,auxData.maxJerk,goalConfig,nil,moveToConfigCallback,auxData,nil)

end七、Lua脚本主函数

function coroutineMain()

simJoints={}

for i=1,6,1 do

simJoints[i]=sim.getObject('./joint',{index=i-1})

end

-- FK movement data:

local initConf={0,0,0,0,0,0}

local vel=180

local accel=40

local jerk=80

local maxVel={vel*math.pi/180,vel*math.pi/180,vel*math.pi/180,vel*math.pi/180,vel*math.pi/180,vel*math.pi/180}

local maxAccel={accel*math.pi/180,accel*math.pi/180,accel*math.pi/180,accel*math.pi/180,accel*math.pi/180,accel*math.pi/180}

local maxJerk={jerk*math.pi/180,jerk*math.pi/180,jerk*math.pi/180,jerk*math.pi/180,jerk*math.pi/180,jerk*math.pi/180}

local initConf={}

local maxConfVel={}

local maxConfAccel={}

local maxConfJerk={}

for i=1,#simJoints,1 do

initConf[i]=sim.getJointPosition(simJoints[i])

maxConfVel[i]=3*math.pi/180

maxConfAccel[i]=1.15

maxConfJerk[i]=0.4

end

fk_data={}

fk_data.maxVel=maxConfVel

fk_data.maxAccel=maxConfAccel

fk_data.maxJerk=maxConfJerk

fk_data.joints=simJoints

-- IK movement data:

local ikMaxVel={0.45,0.45,0.45,4.5}

local ikMaxAccel={0.8,0.8,0.8,0.9}

local ikMaxJerk={0.6,0.6,0.6,0.8}

ik_data={}

ik_data.maxVel=ikMaxVel

ik_data.maxAccel=ikMaxAccel

ik_data.maxJerk=ikMaxJerk

ik_data.ikEnv=ikEnv

ik_data.ikGroup=ikGroup

set_speed(50)

-- Test IK Movement:

--ik_command_demo()

--fk_command_demo()

--sim.wait(5)

--sim.stopSimulation()

while true do

if moveIkMode then

moveIkMode=false

sim.setInt32Signal('moving_status',1) -- Trigger for C++

sim.setStringSignal('moving_signal', 'MOVING') -- Trigger for Python

moveToPose_viaIK(ik_data, targetPos)

sim.setInt32Signal('moving_status',0)

sim.setStringSignal('moving_signal', 'NOT_MOVING')

end

if moveJointMode then

moveJointMode=false

sim.setInt32Signal('moving_status',1)

sim.setStringSignal('moving_signal', 'MOVING')

moveToConfig_viaFK(fk_data, targetJoint)

sim.setInt32Signal('moving_status',0)

sim.setStringSignal('moving_signal', 'NOT_MOVING')

end

end

end参考:

https://marketplace.visualstudio.com/items?itemName=RichardKaiser.cppclrwinf

The End