一、单缸发动机曲轴连杆活塞系统动力学分析参考:

汽车动力总成系统/(伊朗)贝赫鲁兹.马沙迪,(英)戴维.克罗拉著;

白先旭,刘勇强译。——北京:机械工业出版社,2018.6

(汽车先进技术译丛.汽车创新与开发系列)

书名原文:Vehicle Powertrain Systems

ISBN 978-7-111-60005-3

曲柄连杆机构受力分析

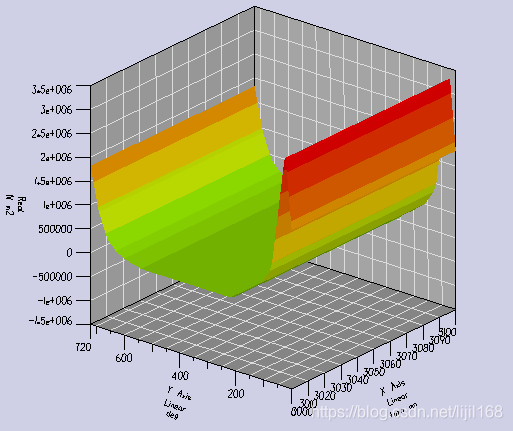

燃烧室压力如下:

X_Column(turn_mn) Y_Column(deg) Z_Column(N_m2)

3000 0 1.82E+06

3000 20 3.24E+06

3000 23 3.29E+06

3000 26 3.24E+06

3000 50 2.03E+06

3000 60 1.52E+06

3000 70 1.01E+06

3000 80 8.10E+05

3000 100 6.08E+05

3000 110 5.07E+05

3000 150 3.04E+05

3000 190 1.22E+05

3000 200 6.08E+04

3000 220 0.00E+00

3000 540 0.00E+00

3000 600 1.01E+05

3000 630 2.03E+05

3000 660 4.05E+05

3000 690 9.12E+05

3000 710 1.52E+06

3000 720 1.82E+06

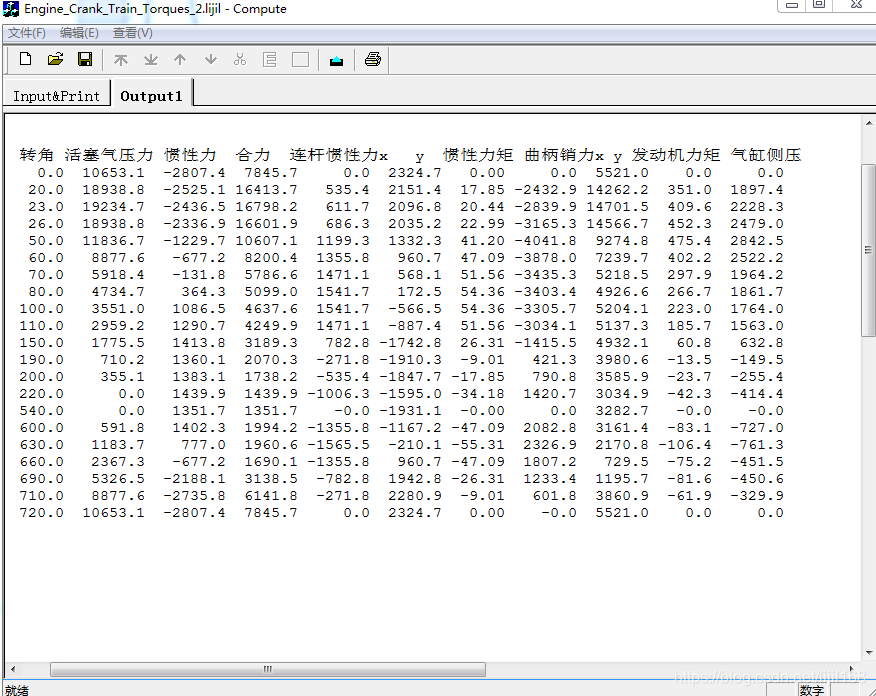

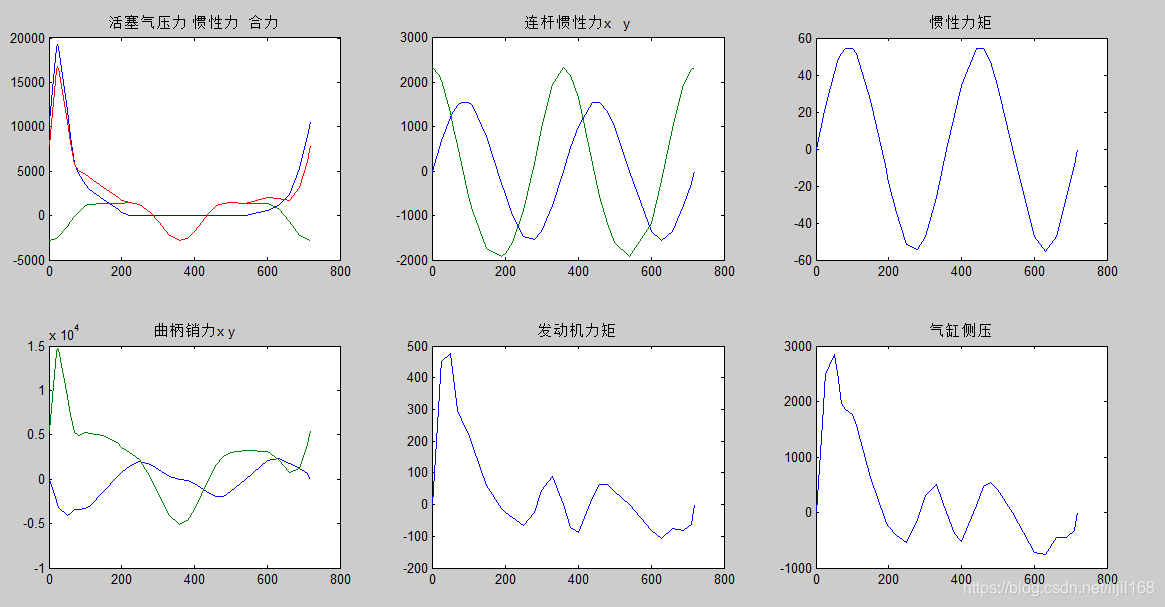

用matlab 编程求解结果如下:

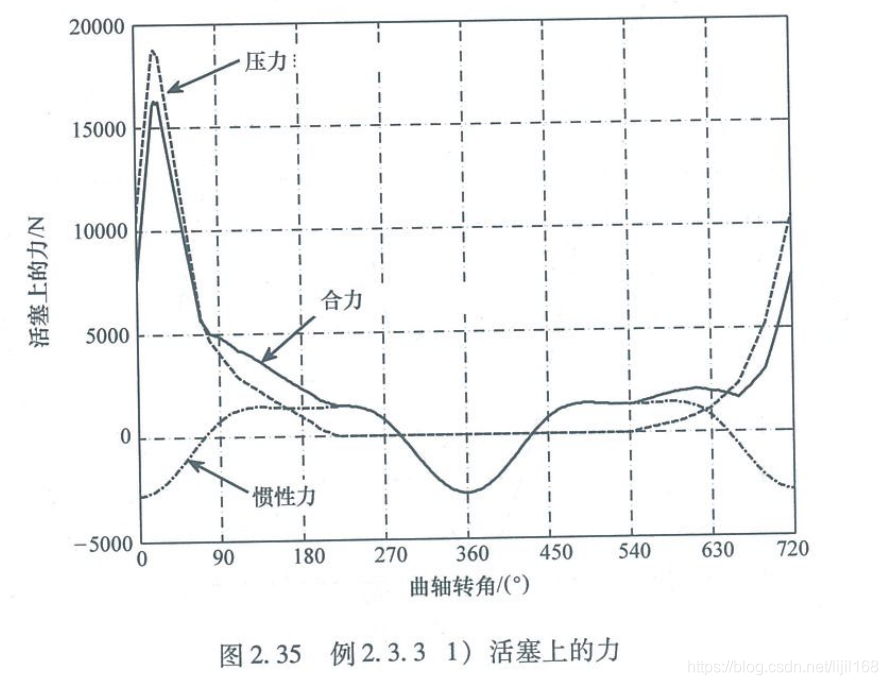

1、活塞受力

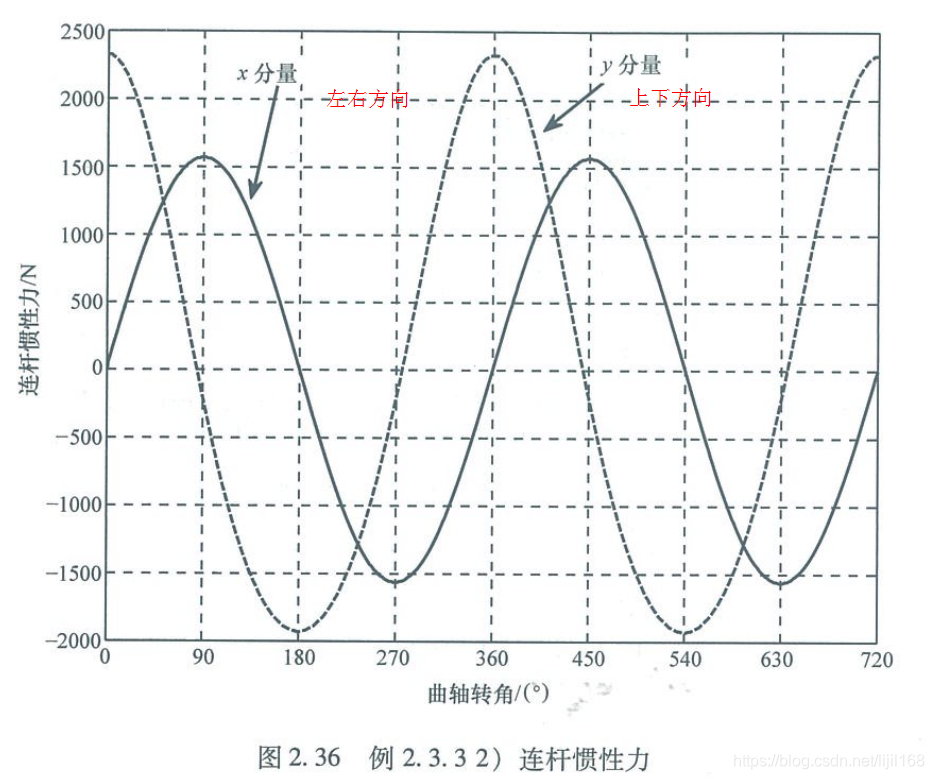

2、连杆惯性力

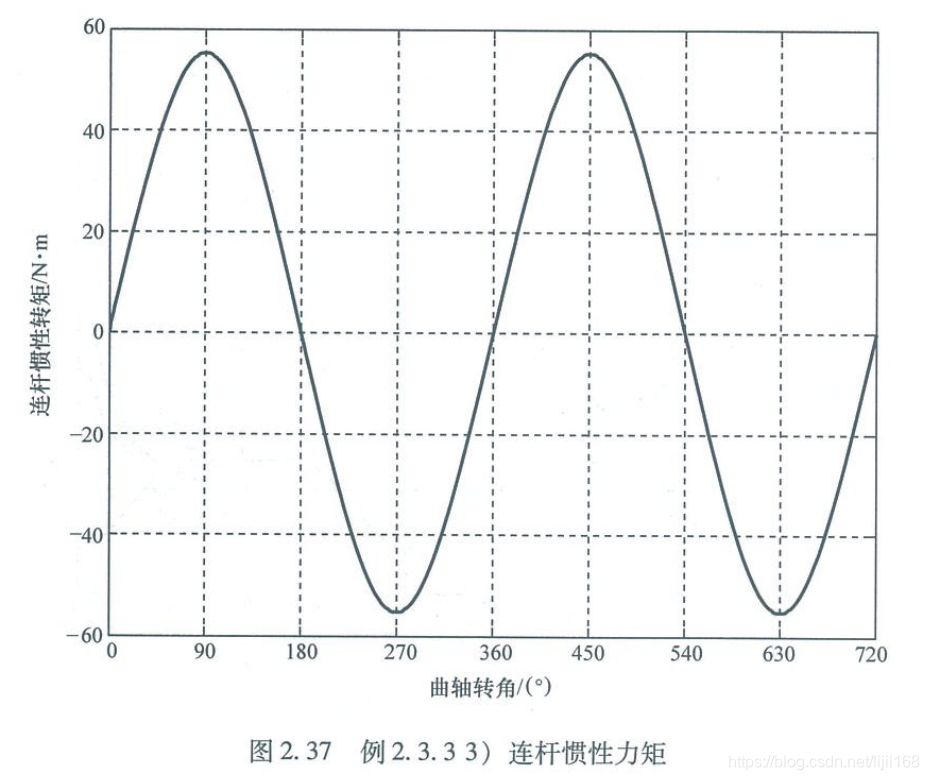

3、连杆惯性力矩

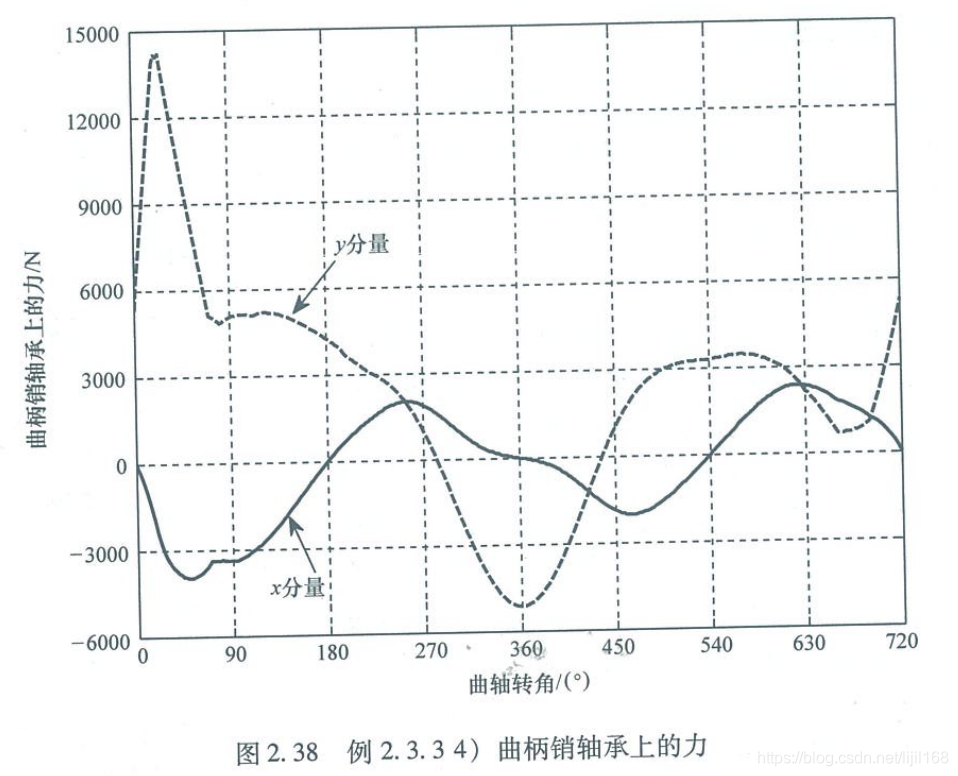

4、曲柄销轴承上的力

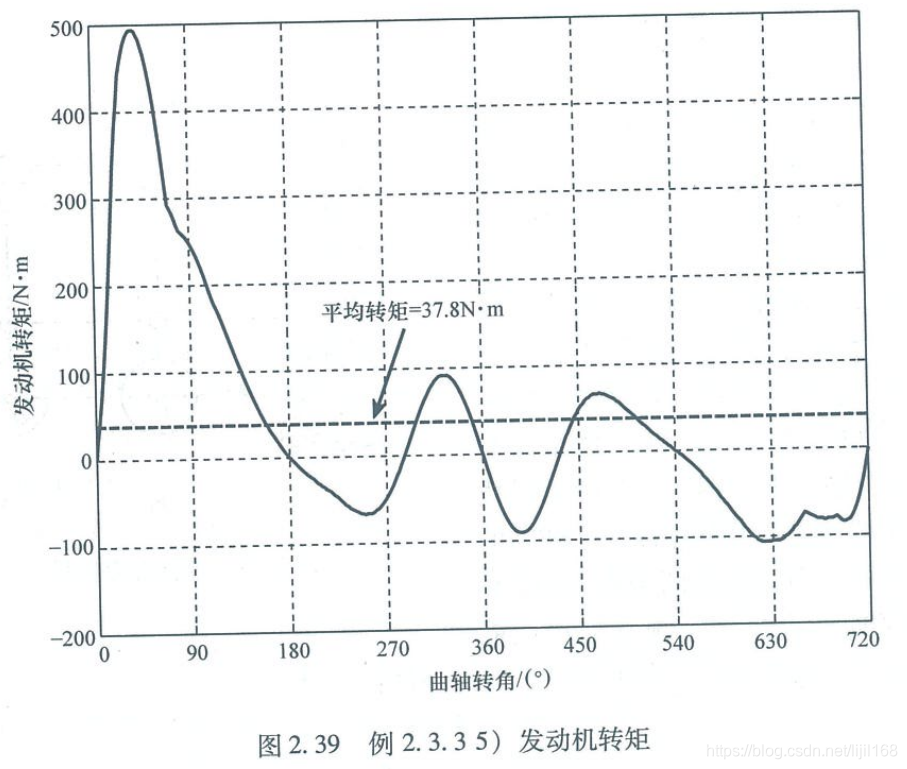

5、发动机转矩

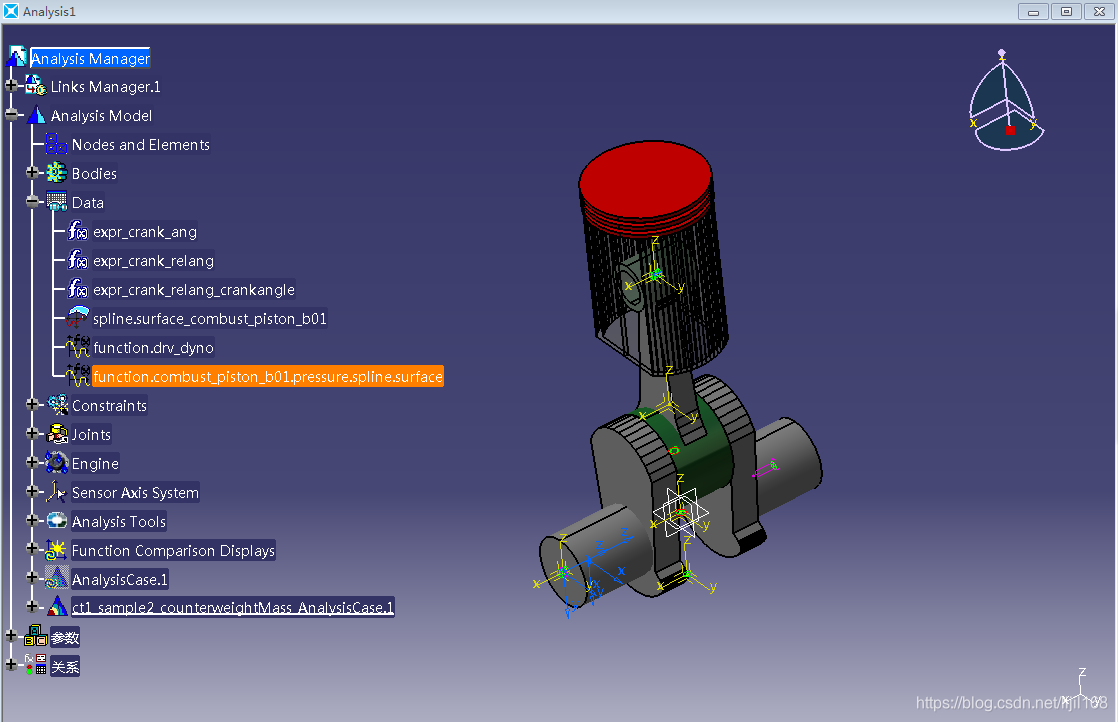

二、virtual.lab motion仿真

1、利用PDS建立单缸发动机模型,然后导入到virtual.lab motion中

2、活塞轴向受力(活塞销受力)

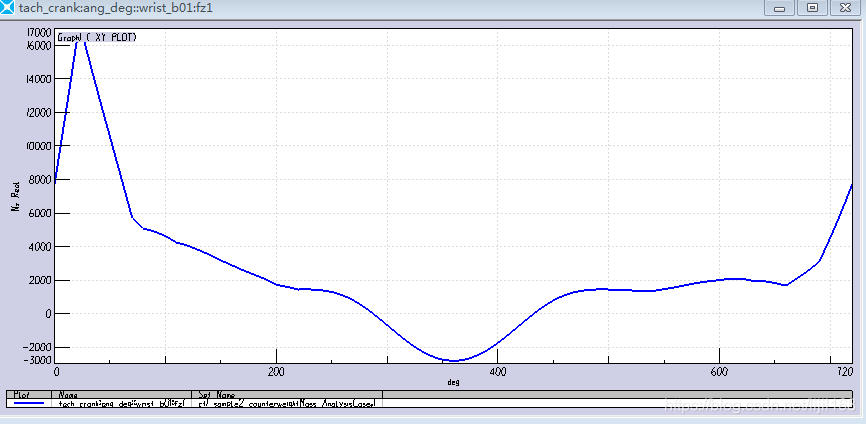

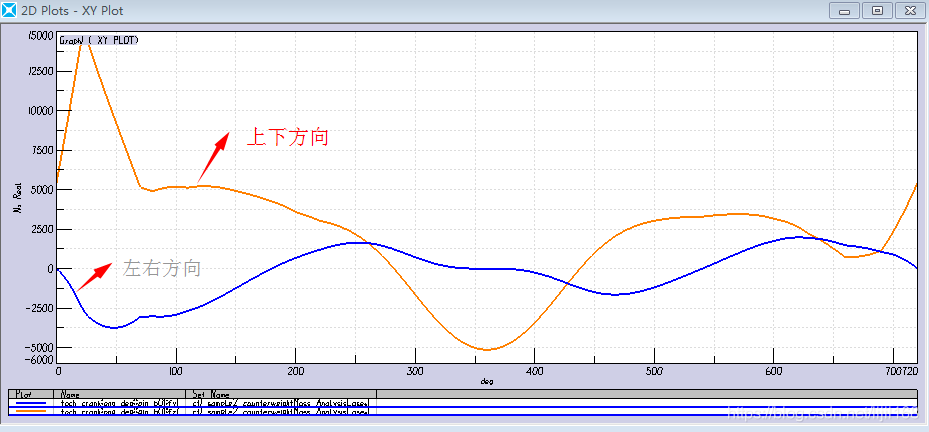

3、曲柄销轴承上的力

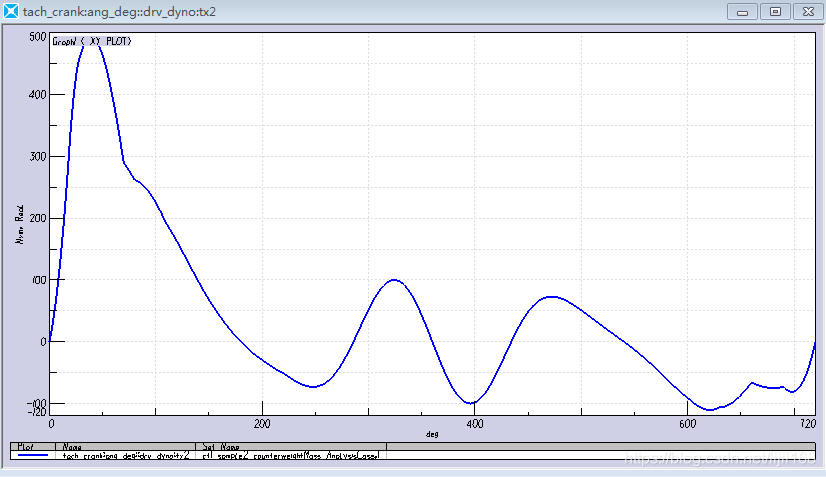

4、发动机转矩

三、总结:virtual.lab motion 仿真的结果与理论计算的结果几乎完全一致!

计算代码如下:

Example2.3.3-Single cylinder,4 stroke-engine torque

-----input-----

pi=3.141593;

mPiston=4.1; %kg

mConnectingRod=4.0; %kg

l=225/1000; %m,Connecting rod pin-pin length

lB=63.054/1000; %m,Connecting rod pin B-CG lengh

R=76/1000; %m,Crank radius

Ap=pi*61.5^2; %mm2,Pistion area

?IC=0.041687-mConnectingRod*lB^2; %kg.m2,Connecting rod inertia

-------Pressure in combustion chamber--------

pr[1][21]=[160.31,162.88,140.14,128.16,51.2,35.12,27.01,21.43,15.12,13.35,8.57,4.16,4.04,3.84,3.08,4.02,6.23,12.94,45.18,125.29,160.31]

ca[1][21]=[0,20,23,26,50,60,70,80,100,110,150,190,200,220,540,600,630,660,690,710,720]

i=0;

omega=1900;

omeg=omega*pi/30;

Rl=R/l; %define ratio R over l

lA=l-lB;

print("转角 活塞气压力 惯性力 合力 连杆惯性力x y 惯性力矩 曲柄销力x y 发动机力矩 气缸侧压")

while(i<21){

ang=ca[0][i]*pi/180

sa=sin(ang);

ca=cos(ang);

s2a=sin(2*ang);

c2a=cos(2*ang);

beta=asin(Rl*sa);

ka=ca+Rl*c2a/cos(beta)+Rl^3*s2a^2/cos(beta)^3/4;

//Piston acceleration:

aP=R*ka*omeg^2;

//Connecting rod angular acceleration:

alpha_c=Rl*omeg^2*sa/cos(beta);

//Connecting rod GC acceleration:

k3=lA*sa/l;

k4=ca+Rl*c2a*lB/cos(beta)/l;

agx=-R*omeg^2*k3;

agy=-R*omeg^2*k4;

ag=sqrt(agx^2+agy^2);

//Piston pressure force:

Fp=pr[0][i]*Ap/9.8;

//Piston inertia force:

FIP=-mPiston*aP;

//Resultant piston force:

FPt=Fp+FIP;

//Connection rod inertia forces(N):

FIx=-mConnectingRod*agx;

FIy=-mConnectingRod*agy;

//Conneting rod inertia torque(Nm):

TIG=IC*alpha_c;

//Crank-pin bearing forces:

Bx=(-FIP-Fp+lB*FIy/l)*tan(beta)-lA*FIx/l-TIG/l/cos(beta);

By=Fp+FIP-FIy;

//Engine torque:

Te=R*(By*sa-Bx*ca);

//气缸壁侧压力:

Fw=-FIx-Bx;

print("%5.1f %8.1f %8.1f %7.1f %7.1f %7.1f %6.2f %7.1f %7.1f %6.1f %7.1f",ca[0][i],Fp,FIP,FPt,FIx,FIy,TIG,Bx,By,Te,Fw)

i=i+1

}matlab 代码:

%Example2.3.3-Single cylinder,4 stroke-engine torque

%-----input-----

%pi=3.141593;

mPiston=430/1000; %kg

mConnectingRod=440/1000; %kg

l=140/1000; %m,Connecting rod pin-pin length

lB=37/1000; %m,Connecting rod pin B-CG lengh

R=49/1000; %m,Crank radius

Ap=5800; %mm2,Pistion area

IC=0.0015; %kg.m2,Connecting rod inertia

%-------Pressure in combustion chamber--------

pr=[18,32,32.5,32,20,15,10,8,6,5,3,1.2,0.6,0,0,0,0,0,0,0,0,0,0,0,0,0,0,1.0,2.0,4,9,15,18];

crank_angle=[0,20,23,26,50,60,70,80,100,110,150,190,200,220,220,250,280,300,330,360,380,400,440,460,480,500,540,600,630,660,690,710,720];

pr=pr';

crank_angle=crank_angle';

%i=0;

omega=3000;

omeg=omega*pi/30;

Rl=R/l; %define ratio R over l

lA=l-lB;

%print("转角 活塞气压力 惯性力 合力 连杆惯性力x y 惯性力矩 曲柄销力x y 发动机力矩 气缸侧压")

%while(i<21){

ang=crank_angle*pi/180;

sa=sin(ang);

ca=cos(ang);

s2a=sin(2*ang);

c2a=cos(2*ang);

beta=asin((Rl*sa));

ka=ca+Rl*c2a./cos(beta)+Rl^3*s2a.^2./cos(beta).^3/4;

% //Piston acceleration:

aP=R*ka*omeg^2;

% //Connecting rod angular acceleration:

alpha_c=Rl*omeg^2*sa./cos(beta);

% //Connecting rod GC acceleration:

k3=lA*sa/l;

k4=ca+Rl*c2a*lB./cos(beta)/l;

agx=-R*omeg^2*k3;

agy=-R*omeg^2*k4;

ag=sqrt(agx.^2+agy.^2);

% //Piston pressure force:

Fp=pr*Ap/9.8;

% //Piston inertia force:

FIP=-mPiston*aP;

% //Resultant piston force:

FPt=Fp+FIP;

% //Connection rod inertia forces(N):

FIx=-mConnectingRod*agx;

FIy=-mConnectingRod*agy;

% //Conneting rod inertia torque(Nm):

TIG=IC*alpha_c;

% //Crank-pin bearing forces:

Bx=(-FIP-Fp+lB*FIy/l).*tan(beta)-lA*FIx/l-TIG/l./cos(beta);

By=Fp+FIP-FIy;

% //Engine torque:

Te=R*(By.*sa-Bx.*ca);

% //气缸壁侧压力:

Fw=-FIx-Bx;

%print("%5.1f %8.1f %8.1f %7.1f %7.1f %7.1f %6.2f %7.1f %7.1f %6.1f %7.1f",ca[0][i],Fp,FIP,FPt,FIx,FIy,TIG,Bx,By,Te,Fw)

%i=i+1

%}

subplot(2,3,1)

plot(crank_angle,[Fp,FIP,FPt]);%活塞气压力 惯性力 合力

title('活塞气压力 惯性力 合力')

subplot(2,3,2)

plot(crank_angle,[FIx,FIy]);%连杆惯性力x y

title('连杆惯性力x y')

subplot(2,3,3)

plot(crank_angle,TIG);%惯性力矩

title('惯性力矩')

subplot(2,3,4)

plot(crank_angle,[Bx,By]);%曲柄销力x y

title('曲柄销力x y')

subplot(2,3,5)

plot(crank_angle,Te);%发动机力矩

title('发动机力矩')

subplot(2,3,6)

plot(crank_angle,Fw);%气缸侧压

title('气缸侧压')

本文详细解析了单缸发动机曲轴连杆活塞系统的动力学特性,包括活塞受力、连杆惯性力、曲柄销轴承力及发动机转矩等关键参数的计算方法。通过MATLAB编程实现理论计算,并与virtual.labmotion仿真结果对比,验证了计算的准确性。

本文详细解析了单缸发动机曲轴连杆活塞系统的动力学特性,包括活塞受力、连杆惯性力、曲柄销轴承力及发动机转矩等关键参数的计算方法。通过MATLAB编程实现理论计算,并与virtual.labmotion仿真结果对比,验证了计算的准确性。

782

782

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?