ST电机MCLib 生成文件比较

参考文章:STM32 PMSM SDK 5.2 training

ST电机库v5.4.4源代码分析(4): 电角度和力矩方向分析(Hall传感器)

speed unit 和 dpp 解释

一、6step不同工作模式下文章的差异

有三种选择,hall传感器。encode传感器,状态观察传感器。

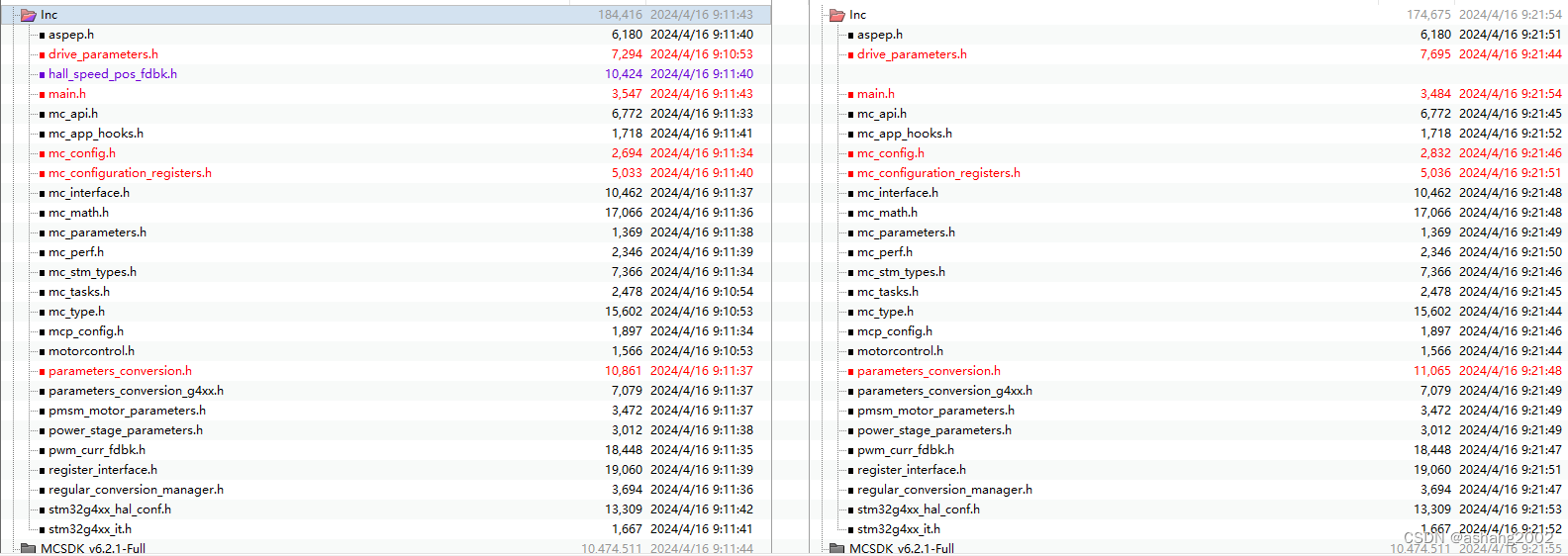

1。头文件比较

-

hall与encoder

hall传感器里多了hall_speed_pos_fdbk.h.

有差异的文件是

driver_parameters.h,

main.h,

mc_config.h,

mc_configuration_registers.h,

parameters_conversion.h -

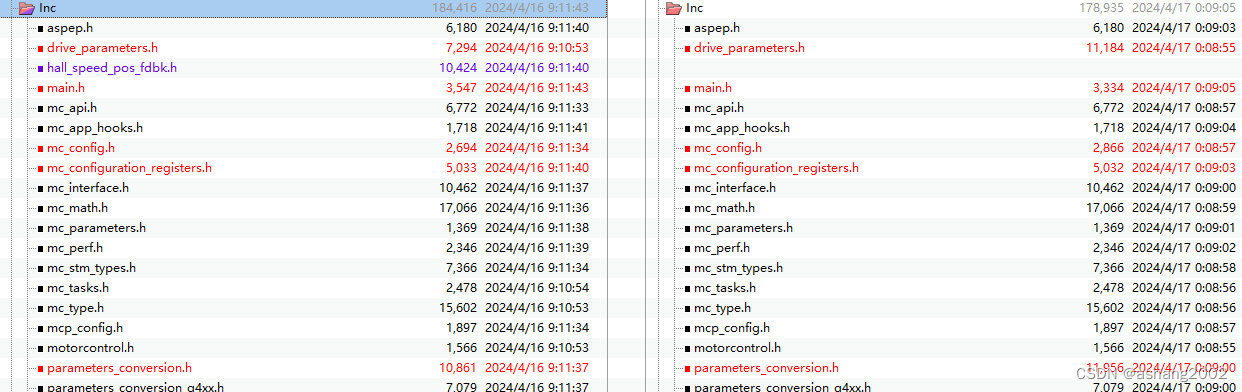

hall与观察传感器

不同的文件与 1 相同。

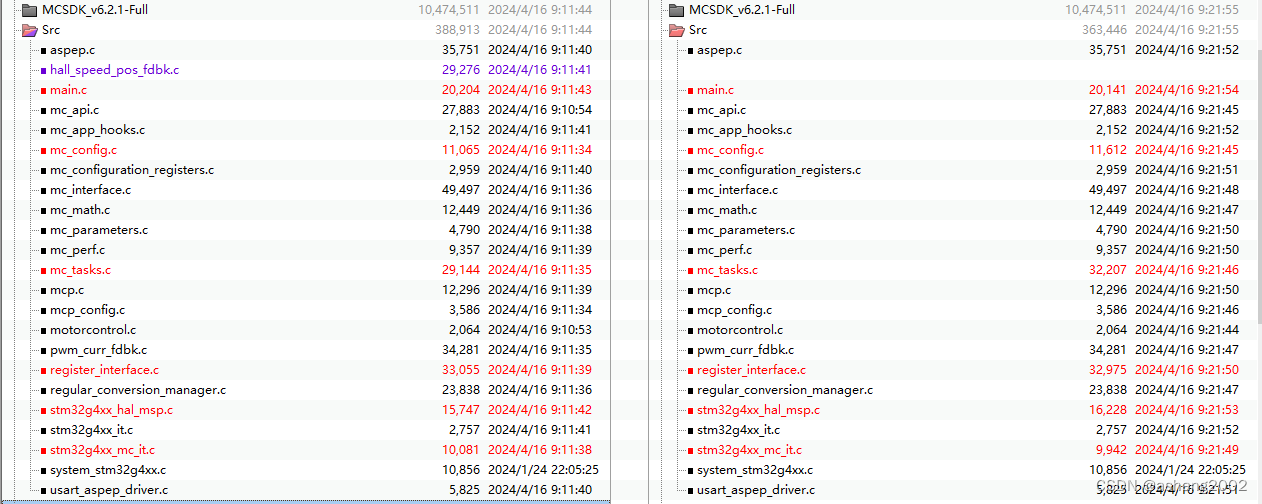

2。源文件比较

-

hall与encoder比较

不同的文件如下:

hall多一个文件: hall_speed_pos_fdbk.c

不同的文件为:

main.c

mc_config.c

mc_task.c

register_interface.c

stm32g4xx_hal_msp.c

stm32g4xx_mc_it,c -

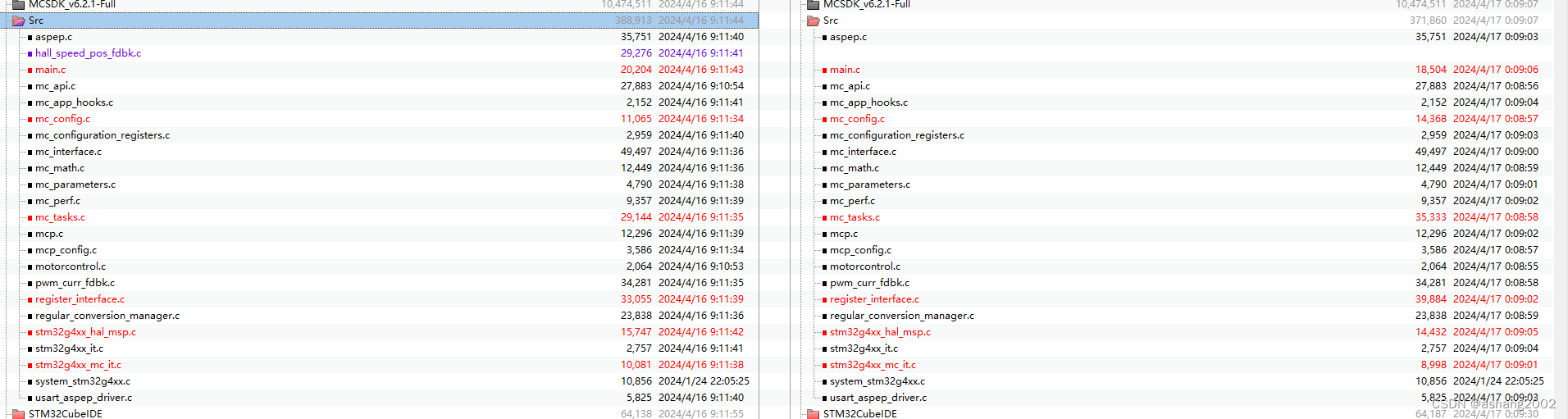

hall与observer比较

不同的文件与上述相同.

二、hall_speed_pos_fdbk.c解析

1。api

void HALL_Init(HALL_Handle_t *pHandle);

void HALL_Clear(HALL_Handle_t *pHandle);

void *HALL_TIMx_UP_IRQHandler(void *pHandleVoid);

void *HALL_TIMx_CC_IRQHandler(void *pHandleVoid);

int16_t HALL_CalcElAngle(HALL_Handle_t *pHandle);

bool HALL_CalcAvrgMecSpeedUnit(HALL_Handle_t *pHandle, int16_t *hMecSpeedUnit);

void HALL_Init(HALL_Handle_t *pHandle):

It initializes the hardware peripherals (TIMx, GPIO and NVIC)

required for the speed position sensor management using HALL

sensors.

2。硬件接口定义:

uint32_t TIMClockFreq;

TIM_TypeDef *TIMx;

uint32_t H1Pin; used,

GPIO_TypeDef *H2Port;

uint32_t ICx_Filter;

3。stm32xxx.h中定义的一些寄存器直接操作及原子操作:

/** @addtogroup Exported_macros

* @{

*/

#define SET_BIT(REG, BIT) ((REG) |= (BIT))

#define CLEAR_BIT(REG, BIT) ((REG) &= ~(BIT))

#define READ_BIT(REG, BIT) ((REG) & (BIT))

#define CLEAR_REG(REG) ((REG) = (0x0))

#define WRITE_REG(REG, VAL) ((REG) = (VAL))

#define READ_REG(REG) ((REG))

#define MODIFY_REG(REG, CLEARMASK, SETMASK) WRITE_REG((REG), (((READ_REG(REG)) & (~(CLEARMASK))) | (SETMASK)))

#define POSITION_VAL(VAL) (__CLZ(__RBIT(VAL)))

/* Use of CMSIS compiler intrinsics for register exclusive access */

/* Atomic 32-bit register access macro to set one or several bits */

#define ATOMIC_SET_BIT(REG, BIT) \

do {

\

uint32_t val; \

do {

\

val = __LDREXW((__IO uint32_t *)&(REG)) | (BIT); \

} while ((__STREXW(val,(__IO uint32_t *)&(REG))) != 0U); \

} while(0)

/* Atomic 32-bit register access macro to clear one or several bits */

#define ATOMIC_CLEAR_BIT(REG, BIT) \

do {

\

uint32_t val; \

do {

\

val = __LDREXW((__IO uint32_t *)&(REG)) & ~(BIT); \

} while ((__STREXW(val,(__IO uint32_t *)&(REG))) != 0U); \

} while(0)

/* Atomic 32-bit register access macro to clear and set one or several bits */

#define ATOMIC_MODIFY_REG(REG, CLEARMSK, SETMASK) \

do {

\

uint32_t val; \

do {

\

val = (__LDREXW((__IO uint32_t *</

本文围绕ST电机MCLib生成文件展开,对比了6step不同工作模式下文章差异,包括头文件和源文件。详细解析了hall_speed_pos_fdbk.c文件,涉及api、硬件接口定义等内容。还介绍了API调用情况,如init mc_task.c mcboot()等,为STM32电机控制开发提供参考。

本文围绕ST电机MCLib生成文件展开,对比了6step不同工作模式下文章差异,包括头文件和源文件。详细解析了hall_speed_pos_fdbk.c文件,涉及api、硬件接口定义等内容。还介绍了API调用情况,如init mc_task.c mcboot()等,为STM32电机控制开发提供参考。

最低0.47元/天 解锁文章

最低0.47元/天 解锁文章

9332

9332

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?