sponge dip-coated CB/MWCNTs/SR conductive composites

在多空聚氨酯(PU)海绵上逐层dip-coating 炭黑CB,MWCNTs,硅橡胶纳米复合材料SR

常用的柔性基底:polydimethylsiloxane(PDMS) 聚二甲硅氧烷,硅橡胶silicon rubber(SR),

聚酰亚胺polyimide (PI),热塑性聚氨酯 thermoplastic polyurethane TPU, 纤维fabric 和聚氨酯海绵 polyurethane PU sponge。【10,11】

基于压阻,电容和压电pizeoresistivity, capacitance, and piezoelectricity【3】原理制造柔性传感器。

具有3维多孔微结构的导电海棉 ,

有几种制造方法:

- reduced graphene oxide(rGO)【17】

- CVD 化学气相沉积【18,19】

- 辅助模板集成策略template-assisted assembly strategy【20】

- physical foaming technology【21】

- 3Dprinting process【22】

- dip-coating 【23】

- EPD 电泳沉积?

CVD成长方法:在精确控制的反应气体混合流下在Ni泡沫上生长石墨烯网络,接下来刻蚀金属骨架获得石墨烯泡沫,这种方法性对来说比较复杂,不容易操作,特别对于刻蚀过程。相对来说,dip-coating技术比较简单。

实验

材料

- 商用PU 密度~0.0386g/cm30.0386g/cm^30.0386g/cm3 <-- 3M company

- MWCNTs 粉末 <-- Chengdu Organic Chemicals Co., Ltd, 平均长度为20um,直径为5nm

- Carbon black CB <-- SPC Chemical Company (Sweden)

- Silicon rubber (SR, GD401) <–Zhonghao Chenguang Co., Ltd (Zigong, China)

- polydimethylsiloxane (PDMS, Sylgard® 184) <-- Dow Corning

- YC-02有机硅导电银胶粘剂 <-- Nanjing Xilite Adhesive Co., Ltd (Nanjing)

- 半透性薄膜 <-- Smith&Nephew Medical Limited 厚度~50um

- 溶剂油(Solvent naphtha) <–Henan Tianfu Chemical Co., Ltd

所有材料买后即用

传感器制造

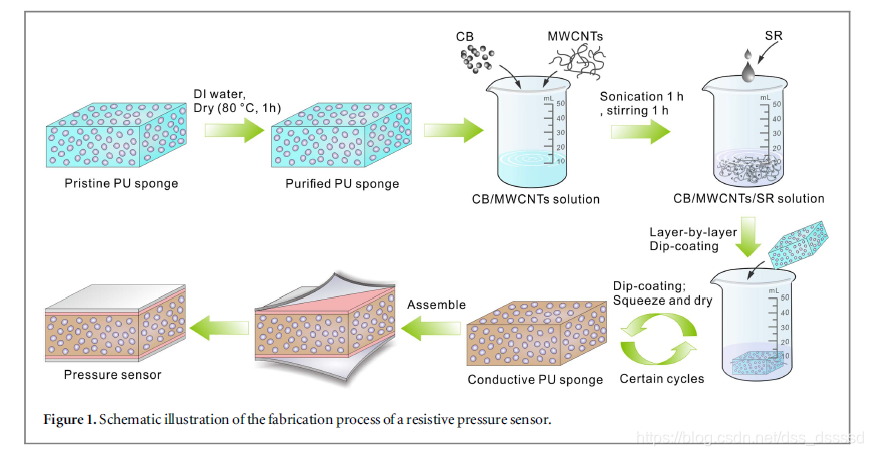

制作示意图如Figure 1,

- PU 海绵在去离子水中清洗几次,基础多余的去离子水,在真空干燥炉【DZF-6021, Shanghai Suopu Instrument Co., Ltd, Shanghai】中80摄氏度下干燥1h,接下来,剪成 10×10mm210 \times 10 mm^210×10mm2的样本,~5mm厚

- 准备CB/MWCNTs 悬浮溶液,CB和MWCNTs粉末按照质量比2:3混合,分散到溶剂油(solvent naphtha)[比如0.3g, 50ml],接下来分别超声处理1h,磁搅拌1h。

- 接下来将室温硫化(RTV)的硅橡胶(例如0.2g)放入CB/MWCNTs的悬浮液中,并用磁棒搅拌1h,获得CB/MWCNTs/SR混合物溶液

- 将PU样本放入溶液中,挤压几次确保溶液完全被海绵吸收,从溶液中取出,在正空干燥炉中,100摄氏度下干燥2h

- 此过程可以操作几次来获得均匀坚固的覆盖效果。获得PU导电海绵

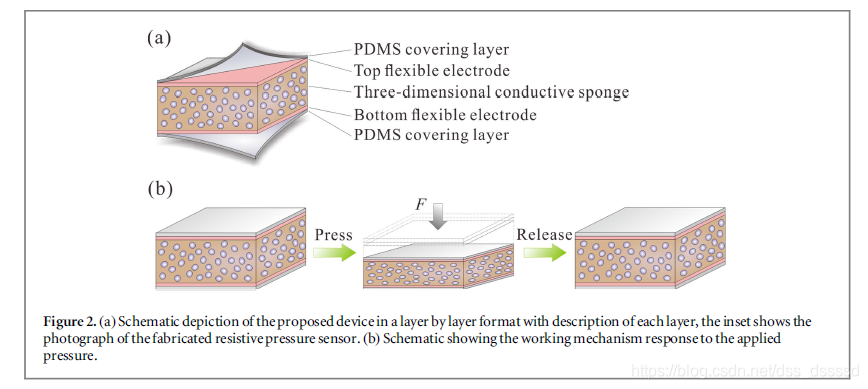

- 将YC-02有机硅导电银胶粘剂作为柔性电极粘贴在导电海绵的上下表面

- 按照pre-polymer 和curing agent (固化剂) 10:1的比列混合PDMS, 磁搅拌10min,脱气(degassed) 30min。PDMS薄膜~50um,覆盖在电极上作为覆盖层。

最终的效果图:

表征:

The microstructures of the pristine polyurethane sponge and polyurethane sponge coated with CB/MWCNTs/

SR composite were characterized by field emission scanning electron microscopy (SU8020, Hitachi). X-ray

diffraction (XRD) patterns (using aD/MAX2500 V, Rigaku) were collected to characterize the degree of

nanocomposites. The current-voltage (I-V ) curves of the piezoresistive strain sensor under different pressure

were obtained by using Keithley 4200. Mechanical compressional tests were performed with a universal testing

machine (LS-WD-100, Shenzhen Lisen electrical technology Co., Ltd). The relative resistance under different

pressure were obtained by aDCresistance meter (TH2515, Changzhou Tonghui electronics Co., Ltd). Dynamic

response time of the device was performed by USB6211DAQ(NI) and viewed via LabVIEW system.

本文介绍了一种通过dip-coating技术在多孔聚氨酯海绵上涂覆炭黑CB、MWCNTs及硅橡胶SR纳米复合材料,制备具有三维多孔结构的导电海绵,用于柔性传感器的制造。传感器利用压阻、电容和压电原理工作,适用于多种柔性基底材料。实验详细描述了材料选择、制备流程及表征方法。

本文介绍了一种通过dip-coating技术在多孔聚氨酯海绵上涂覆炭黑CB、MWCNTs及硅橡胶SR纳米复合材料,制备具有三维多孔结构的导电海绵,用于柔性传感器的制造。传感器利用压阻、电容和压电原理工作,适用于多种柔性基底材料。实验详细描述了材料选择、制备流程及表征方法。

846

846

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?