#include "modelDeemo.h"

#include "version.txt"

// excerpt-export-start

int __stdcall DllMain(void *,unsigned, void *) {

return 1;

}

extern "C" EXPORT_TAG const char *getName() {

#ifdef MODELDEBUG

return "cmodelDeemod";

#else

return "cmodelDeemo";

#endif

}

extern "C" EXPORT_TAG unsigned getMajorVersion() {

return MAJOR_VERSION;

}

extern "C" EXPORT_TAG unsigned getMinorVersion() {

return UPDATE_VERSION;

}

extern "C" EXPORT_TAG void *createInstance() {

models::ModelDeemo *m = new models::ModelDeemo();

return (void *)m;

}

// excerpt-export-end

namespace models {

// excerpt-con-start

ModelDeemo::ModelDeemo() : bulk_(0.0), Mshear_(0.0), Mviscosity1_(0.0), Kshear1_(0.0), Kviscosity1_(0.0), Kshear2_(0.0), Kviscosity2_(0.0), Mviscosity2_(0.0), A_(0.0) {

//kelvinStrain1

Mekd_[0] = 0.0;

Mekd_[1] = 0.0;

Mekd_[2] = 0.0;

Mekd_[3] = 0.0;

Mekd_[4] = 0.0;

Mekd_[5] = 0.0;

//kelvinStrain2

Mekd_[6] = 0.0;

Mekd_[7] = 0.0;

Mekd_[8] = 0.0;

Mekd_[9] = 0.0;

Mekd_[10] = 0.0;

Mekd_[11] = 0.0;

}

// excerpt-con-end

String ModelDeemo::getName() const {

#ifdef MODELDEBUG

return L"Deemo-debug";

#else

return L"Deemo";

#endif

}

String ModelDeemo::getFullName() const {

#ifdef MODELDEBUG

return L"Deemo Debug";

#else

return L"Deemo";

#endif

}

UInt ModelDeemo::getMinorVersion() const {

return UPDATE_VERSION;

}

String ModelDeemo::getProperties() const { //获取参数

return L"bulk_, Kshear1_, Mshear_, Kviscosity1_, Mviscosity1_,"//burgers的参数

L"Kshear2_, Kviscosity2_, Mviscosity2_, A_," //塑性部分的参数

L"strain-kelvin-xx,strain-kelvin-yy,strain-kelvin-zz,strain-kelvin-xy,strain-kelvin-xz,strain-kelvin-yz,"//黏弹性体应变

L"cohesion,friction,dilation,tension,strain-shear-plastic,strain-tensile-plastic -strain-tension-plastic";//MC准则

}

String ModelDeemo::getStates() const {

return L"shear-n,tension-n,shear-p,tension-p";

}

Variant ModelDeemo::getProperty(UInt index) const {

switch (index) {

case 1: return bulk_;

case 2: return Kshear1_;

case 3: return Mshear_;

case 4: return Kviscosity1_;

case 5: return Mviscosity1_;

case 6: return Kshear2_;

case 7: return Kviscosity2_;

case 8: return Mviscosity2_;

case 9: return A_;//模型参数

case 10: return Mekd_[0];

case 11: return Mekd_[1];

case 12: return Mekd_[2];

case 13: return Mekd_[3];

case 14: return Mekd_[4];

case 15: return Mekd_[5];

case 16: return Mekd_[6];

case 17: return Mekd_[7];

case 18: return Mekd_[8];

case 19: return Mekd_[9];

case 20: return Mekd_[10];

case 21: return Mekd_[11];

case 22: return cohesion_;

case 23: return friction_;

case 24: return dilation_;

case 25: return tension_;

case 26: return sHP_;//剪切应变

case 27: return tHP_;//张拉应变

}

return(0.0);

}

void ModelDeemo::setProperty(UInt index,const Variant &p,UInt restoreVersion) {

ConstitutiveModel::setProperty(index, p, restoreVersion);

switch (index) {

case 1: bulk_ = p.toDouble(); break;

case 2: Kshear1_ = p.toDouble(); break;

case 3: Mshear_ = p.toDouble(); break;

case 4: Kviscosity1_ = p.toDouble(); break;

case 5: Mviscosity1_ = p.toDouble(); break;

case 6: Kshear2_ = p.toDouble(); break;

case 7: Kviscosity2_ = p.toDouble(); break;

case 8: Mviscosity2_ = p.toDouble(); break;

case 9: A_ = p.toDouble(); break;

case 10: Mekd_[0] = p.toDouble(); break;

case 11: Mekd_[1] = p.toDouble(); break;

case 12: Mekd_[2] = p.toDouble(); break;

case 13: Mekd_[3] = p.toDouble(); break;

case 14: Mekd_[4] = p.toDouble(); break;

case 15: Mekd_[5] = p.toDouble(); break;

case 16: Mekd_[6] = p.toDouble(); break;

case 17: Mekd_[7] = p.toDouble(); break;

case 18: Mekd_[8] = p.toDouble(); break;

case 19: Mekd_[9] = p.toDouble(); break;

case 20: Mekd_[10] = p.toDouble(); break;

case 21: Mekd_[11] = p.toDouble(); break;

case 22: cohesion_ = p.toDouble(); break;

case 23: friction_ = p.toDouble(); break;

case 24: dilation_ = p.toDouble(); break;

case 25: tension_ = p.toDouble(); break;

case 26: sHP_ = p.toDouble(); break;

case 27: tHP_ = p.toDouble(); break;

}

}

/*bool ModelDeemo::isPropertyAdvanced(UInt i) const {

if (i <= 4)

return ModelDeemo::isPropertyAdvanced(i);

else if (i==9)

return true;

return false;

}*/

//下面这段cvisc中是vm,这里是mm

void ModelDeemo::copy(const ConstitutiveModel *m) {

const ModelDeemo *mm = dynamic_cast<const ModelDeemo *>(m);

if (!mm) throw std::runtime_error("Internal error: constitutive model dynamic cast failed.");

//

ConstitutiveModel::copy(m);

//

bulk_ = mm->bulk_;

Kshear1_ = mm->Kshear1_;

Mshear_ = mm->Mshear_;

Kviscosity1_ = mm->Kviscosity1_;

Mviscosity1_ = mm->Mviscosity1_;

Kshear2_ = mm->Kshear2_;

Kviscosity2_ = mm->Kviscosity2_;

Mviscosity2_ = mm->Mviscosity2_;

A_ = mm->A_;

Mekd_[0] = mm->Mekd_[0];

Mekd_[1] = mm->Mekd_[1];

Mekd_[2] = mm->Mekd_[2];

Mekd_[3] = mm->Mekd_[3];

Mekd_[4] = mm->Mekd_[4];

Mekd_[5] = mm->Mekd_[5];

Mekd_[6] = mm->Mekd_[6];

Mekd_[7] = mm->Mekd_[7];

Mekd_[8] = mm->Mekd_[8];

Mekd_[9] = mm->Mekd_[9];

Mekd_[10] = mm->Mekd_[10];

Mekd_[11] = mm->Mekd_[11];

cohesion_ = mm->cohesion_;

friction_ = mm->friction_;

dilation_ = mm->dilation_;

tension_ = mm->tension_;

sHP_ = mm->sHP_;

tHP_ = mm->tHP_;

}

// excerpt-run-start参数初始化,计算模型中间参数值;

void ModelDeemo::initialize(UByte d,State *s) {

ConstitutiveModel::initialize(d,s);

//参数非零化

if (Mshear_ <= 0.0) Mshear_ = 1e-20;

if (Kshear1_ <= 0.0) Kshear1_ = 0.0;

if (Kshear2_ <= 0.0) Kshear2_ = 0.0;

if (Kviscosity1_ <= 0.0) {

Kviscosity1_ = 0.0;

Kshear1_ = 0.0;

}

if (Kviscosity2_ <= 0.0) {

Kviscosity2_ = 0.0;

Kshear2_ = 0.0;

}

if (Mviscosity1_ <= 0.0) Mviscosity1_ = 0.0;

if (Mviscosity2_ <= 0.0) Mviscosity2_ = 0.0;

if (A_ <= 0.0) A_ = 0.0;

// 3. 初始化Mohr-Coulomb准则相关参数(参考CVisc模型)

Double rsin = std::sin(friction_ * degrad); // degrad是角度转弧度的系数

nph_ = (1.0 + rsin) / (1.0 - rsin); // 塑性硬化参数

csn_ = 2.0 * cohesion_ * sqrt(nph_); // 修正后的内聚力

// 限制抗拉强度不超过内聚力和摩擦角决定的顶点值

if (friction_ > 0.0) {

Double apex = cohesion_ / std::tan(friction_ * degrad);

tension_ = std::min(tension_, apex);

}

// 剪胀角相关参数

rsin = std::sin(dilation_ * degrad);

nps_ = (1.0 + rsin) / (1.0 - rsin); // 剪胀参数

// 计算应力比参数

rc_ = std::sqrt(1.0 + nph_ * nph_);

}

static const UInt Dqs = 12;

static const UInt Dqt = 13;

void ModelDeemo::run(UByte d,State *s) {

ConstitutiveModel::run(d,s);

// excerpt-state-start

if (s->state_ & shear_now) s->state_ |= shear_past;

s->state_ &= ~shear_now;

if (s->state_ & tension_now) s->state_ |= tension_past;

s->state_ &= ~tension_now;

// excerpt-state-end

UInt iPlas = 0;//未屈服(黏弹性)

// dEkd values now stored in s->working_[] array (necessary for thread safety)

Double tempk1 = 0, tempk2 = 0, tempm1 = 0, tempm2 = 0.0;

Double dCrtdel = (s->isCreep() ? s->getTimeStep() : 0.0);

Double dSubZoneVolume = s->getSubZoneVolume();

if (!s->sub_zone_) {

s->working_[0] = 0.0;

s->working_[1] = 0.0;

s->working_[2] = 0.0;

s->working_[3] = 0.0;

s->working_[4] = 0.0;

s->working_[5] = 0.0;

s->working_[6] = 0.0;

s->working_[7] = 0.0;

s->working_[8] = 0.0;

s->working_[9] = 0.0;

s->working_[10] = 0.0;

s->working_[11] = 0.0;

s->working_[Dqs] = 0.0;

s->working_[Dqt] = 0.0;

}

if (Kviscosity1_ <= 0.0) tempk1 = 0.0;

else tempk1 = 1.0 / Kviscosity1_;

//

if (Mviscosity1_ <= 0.0) tempm1 = 0.0;

else tempm1 = 1.0 / Mviscosity1_;

if (Kviscosity2_ <= 0.0) tempk2 = 0.0;

else tempk2 = 1.0 / Kviscosity2_;

if (Mviscosity2_ <= 0.0) tempm2 = 0.0;

else tempm2 = 1.0 / Mviscosity2_;

Double temp1 = 0.5 * Kshear1_ * dCrtdel * tempk1;

Double a1_con = 1.0 + temp1;//A1

Double b1_con = 1.0 - temp1;//B1

Double ba1 = b1_con / a1_con;

Double bac1 = ba1 - 1.0;//(B1/A1-1)

Double temp2 = 0.5 * Kshear2_ * dCrtdel * tempk2;

Double a2_con = 1.0 + temp2;//A2

Double b2_con = 1.0 - temp2;//B2

Double ba2 = b2_con / a2_con;

Double bac2 = ba2 - 1.0;//(B2/A2-1)

Double tempb = (tempm1 + tempk1 / a1_con+ tempk2 / a2_con) * dCrtdel * 0.25;

Double tempa = 0.5 / Mshear_;

Double x_con = tempa + tempb;//a

Double y_con = tempa - tempb;//b

Double z1_con = dCrtdel * tempk1 / (4.0 * a1_con);

Double z2_con = dCrtdel * tempk2 / (4.0 * a2_con);

//Double z_con = z1_con + z2_con;//

Double c1dxc = 1.0 / x_con;//1/a

//;--- partition strains ---

Double dev = s->stnE_.s11() + s->stnE_.s22() + s->stnE_.s33();

Double dev3 = d1d3 * dev;

Double de11d = s->stnE_.s11() - dev3;

Double de22d = s->stnE_.s22() - dev3;

Double de33d = s->stnE_.s33() - dev3;//应变计算

//;--- partition stresses---

Double s0 = d1d3 * (s->stnS_.s11() + s->stnS_.s22() + s->stnS_.s33());

Double s11d = s->stnS_.s11() - s0;

Double s22d = s->stnS_.s22() - s0;

Double s33d = s->stnS_.s33() - s0;//应力计算

//;--- remember old stresses ---

Double s11old = s11d;

Double s22old = s22d;

Double s33old = s33d;

Double s12old = s->stnS_.s12();

Double s13old = s->stnS_.s13();

Double s23old = s->stnS_.s23();

//;--- new trial deviator stresses assuming viscoelastic increments ---

s11d = (de11d + s11d * y_con - Mekd_[0] * bac1) * c1dxc;

s22d = (de22d + s22d * y_con - Mekd_[1] * bac1) * c1dxc;

s33d = (de33d + s33d * y_con - Mekd_[2] * bac1) * c1dxc;

Double s12i = (s->stnE_.s12() + s->stnS_.s12() * y_con - Mekd_[3] * bac1) * c1dxc;

Double s13i = (s->stnE_.s13() + s->stnS_.s13() * y_con - Mekd_[4] * bac1) * c1dxc;

Double s23i = (s->stnE_.s23() + s->stnS_.s23() * y_con - Mekd_[5] * bac1) * c1dxc;

//;--- new trial isotropic stress assuming elastic increment ---

s0 += bulk_ * dev;

Double s11i = s11d + s0;

Double s22i = s22d + s0;

Double s33i = s33d + s0;

//; --- trial stresses ---

s->stnS_.rs11() = s11i;

s->stnS_.rs22() = s22i;

s->stnS_.rs33() = s33i;

s->stnS_.rs12() = s12i;

s->stnS_.rs13() = s13i;

s->stnS_.rs23() = s23i;

//先标定了没有进入塑性的部分

//下面是在做塑性状态的判断

if (canFail()) {

SymTensorInfo info;

DVect3 prin = s->stnS_.getEigenInfo(&info);

Double e1_ = bulk_ + d2d3 * c1dxc;//α1

Double e2_ = bulk_ - d1d3 * c1dxc;//α2

Double ra = e1_ - nps_ * e2_;

//Double e21_ = e2_ / e1_;

Double rb = e2_ * (1.0 - nps_);

Double rd = e2_ - nps_ * e1_;//应力更新公式的λ的系数

//定义塑性部分相关参数

Double G3 = Kshear2_; // 开尔文体弹性模量 (对应Kshear2_)

Double A = A_; // 非线性黏壶参数

Double fs = -prin.x() + nph_ * prin.z() - csn_;

Double ftz = prin.z() - tension_;

Double fty = prin.y() - tension_;

Double ftx = prin.x() - tension_;//MC破坏准则

Double fsd = fs / rc_;//(归一化但是还没搞清楚是啥)

Double lambda_s_1 = fs / (2 * G3)*(1.0 - exp(-G3 * tempk2 * dCrtdel)); //λs1

Double lambda_s_2 = fs * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1); //λs2

Double lambda_s = lambda_s_1+ lambda_s_2;//λs

Double beta_s_xt = ftx / (2 * G3)*(1.0 - exp(-G3 * tempk2 * dCrtdel));//βx

Double gamma_s_xt = ftx * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);//γx

Double lambda_s_xt = beta_s_xt + gamma_s_xt;//λsxt

Double beta_s_yt = fty / (2 * G3)*(1.0 - exp(-G3 * tempk2 * dCrtdel));//βy

Double gamma_s_yt = fty * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);//γy

Double lambda_s_yt = beta_s_yt + gamma_s_yt;//λsyt

Double beta_s_zt = ftz / (2 * G3)*(1.0 - exp(-G3 * tempk2 * dCrtdel));//βz

Double gamma_s_zt = ftz * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);//γz

Double lambda_s_zt = beta_s_zt + gamma_s_zt;//λszt

if (iPlas == 0) {

// 塑性未激活:仅用第一个 Kelvin 元件(原逻辑)

s11d = (de11d + s11d * y_con - Mekd_[0] * bac1) * c1dxc;

s22d = (de22d + s22d * y_con - Mekd_[1] * bac1) * c1dxc;

s33d = (de33d + s33d * y_con - Mekd_[2] * bac1) * c1dxc;

s12i = (s->stnE_.s12() + s->stnS_.s12() * y_con - Mekd_[3] * bac1) * c1dxc;

s13i = (s->stnE_.s13() + s->stnS_.s13() * y_con - Mekd_[4] * bac1) * c1dxc;

s23i = (s->stnE_.s23() + s->stnS_.s23() * y_con - Mekd_[5] * bac1) * c1dxc;

}

else {

//Double s11_2 = (-m2_ + std::sqrt((m2_)*(m2_)+4 * m1_*s11d)) / (2 * m1_);

//Double s22_2 = (-m2_ + std::sqrt((m2_)*(m2_)+4 * m1_*s22d)) / (2 * m1_);

//Double s33_2 = (-m2_ + std::sqrt((m2_)*(m2_)+4 * m1_*s33d)) / (2 * m1_);

//Double s12_2 = (-m2_ + std::sqrt((m2_)*(m2_)+4 * m1_*s->stnS_.s12())) / (2 *m1_);

//Double s13_2 = (-m2_ + std::sqrt((m2_)*(m2_)+4 * m1_*s->stnS_.s13())) / (2 *m1_);

//Double s23_2 = (-m2_ + std::sqrt((m2_)*(m2_)+4 * m1_*s->stnS_.s23())) / (2 *m1_);

//非线性牛顿体

Double s11_2 = s11d * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);

Double s22_2 = s22d * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);

Double s33_2 = s33d * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);

Double s12_2 = s->stnS_.s12() * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);

Double s13_2 = s->stnS_.s13() * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);

Double s23_2 = s->stnS_.s23() * tempm2 / (2 * A)*(exp(A* dCrtdel) - 1);

// 塑性已激活:使用两个 Kelvin 元件和一个非线性牛顿体

s11d = (de11d + s11d * y_con - s11_2 - Mekd_[0] * bac1 - Mekd_[6] * bac2) * c1dxc;

s22d = (de22d + s22d * y_con - s22_2 - Mekd_[1] * bac1 - Mekd_[7] * bac2) * c1dxc;

s33d = (de33d + s33d * y_con - s33_2 - Mekd_[2] * bac1 - Mekd_[8] * bac2) * c1dxc;

s12i = (s->stnE_.s12() + s->stnS_.s12() * y_con - s12_2 - Mekd_[3] * bac1 - Mekd_[9] * bac2) * c1dxc;

s13i = (s->stnE_.s13() + s->stnS_.s13() * y_con - s13_2 - Mekd_[4] * bac1 - Mekd_[10] * bac2) * c1dxc;

s23i = (s->stnE_.s23() + s->stnS_.s23() * y_con - s23_2 - Mekd_[5] * bac1 - Mekd_[11] * bac2) * c1dxc;

}

if (fsd > 0.0 && fsd >= ftz) {//剪切塑性修正

iPlas = 1;

s->state_ |= shear_now;

prin.rx() += lambda_s * ra;

prin.ry() += lambda_s * rb;

prin.rz() += lambda_s * rd;//已检查

}

else if (ftz > 0.0 && ftz >= fsd) {

s->state_ |= tension_now;//拉伸塑性修正

if (ftx > 0.0) {

iPlas = 4;

prin.rx() -= lambda_s_xt * e1_ + (lambda_s_yt + lambda_s_zt) * e2_;

prin.ry() -= lambda_s_yt * e1_ + (lambda_s_xt + lambda_s_zt) * e2_;

prin.rz() -= lambda_s_zt * e1_ + (lambda_s_xt + lambda_s_yt) * e2_;//三个主应力失效

}

else if (fty > 0.0) {

iPlas = 3;

prin.rx() -= (lambda_s_yt + lambda_s_zt) * e2_;

prin.ry() -= (lambda_s_zt * e2_ + lambda_s_yt * e1_);

prin.rz() -= (lambda_s_zt * e1_ + lambda_s_yt * e2_);//两个主应力失效

}

else {

iPlas = 2;

//Double tco = ftz * e21_;//应该是用不上了

prin.rx() -= lambda_s_zt * e2_ ;

prin.ry() -= lambda_s_zt * e2_ ;

prin.rz() -= lambda_s_zt * e1_ ;//一个主应力失效

}

}

if (friction_ > 0.0) {

Double apex = cohesion_ / tan(friction_*degrad);

if (prin.x() >= apex || prin.y() >= apex || prin.z() >= apex) {//如果任意方向上的应力超过这个阈值,进入拉伸状态

iPlas = 4;

s->state_ |= tension_now;

prin.rx() = apex;

prin.ry() = apex;

prin.rz() = apex;

}

}

if (iPlas) {

s->stnS_ = info.resolve(prin);//用当前的prin应力来解析并更新应力状态

if (iPlas == 1) {

Double dDe1p = -lambda_s;//1方向的塑性应变增量

Double dDe3p = -1 * lambda_s * nps_;//3方向的塑性应变增量

Double dDepa = d1d3 * (dDe1p + dDe3p);

dDe1p -= dDepa;

dDe3p -= dDepa;

s->working_[Dqs] += sqrt(0.5 * (dDe1p*dDe1p + dDepa * dDepa + dDe3p * dDe3p)) * dSubZoneVolume;

}

if (iPlas == 2) {

Double dAux = lambda_s_zt;

s->working_[Dqt] += dAux * dSubZoneVolume;

}

if (iPlas == 3) {

Double dAux = lambda_s_zt + lambda_s_yt;

s->working_[Dqt] += dAux * dSubZoneVolume;

}

if (iPlas == 4) {

Double dAux = lambda_s_zt + lambda_s_yt + lambda_s_xt;

s->working_[Dqt] += dAux * dSubZoneVolume;

}

}

}

//--- sub-zone contribution to Kelvin1-strains ---

s0 = d1d3 * (s->stnS_.s11() + s->stnS_.s22() + s->stnS_.s33());

s->working_[0] += (Mekd_[0] * ba1 + (s->stnS_.s11() - s0 + s11old) * z1_con) * s->getSubZoneVolume();

s->working_[1] += (Mekd_[1] * ba1 + (s->stnS_.s22() - s0 + s22old) * z1_con) * s->getSubZoneVolume();

s->working_[2] += (Mekd_[2] * ba1 + (s->stnS_.s33() - s0 + s33old) * z1_con) * s->getSubZoneVolume();

s->working_[3] += (Mekd_[3] * ba1 + (s->stnS_.s12() + s12old) * z1_con) * s->getSubZoneVolume();

s->working_[4] += (Mekd_[4] * ba1 + (s->stnS_.s13() + s13old) * z1_con) * s->getSubZoneVolume();

s->working_[5] += (Mekd_[5] * ba1 + (s->stnS_.s23() + s23old) * z1_con) * s->getSubZoneVolume();

//--- sub-zone contribution to Kelvin2-strains ---

s->working_[6] += (Mekd_[6] * ba2 + (s->stnS_.s11() - s0 + s11old) * z2_con) * s->getSubZoneVolume();

s->working_[7] += (Mekd_[7] * ba2 + (s->stnS_.s22() - s0 + s22old) * z2_con) * s->getSubZoneVolume();

s->working_[8] += (Mekd_[8] * ba2 + (s->stnS_.s33() - s0 + s33old) * z2_con) * s->getSubZoneVolume();

s->working_[9] += (Mekd_[9] * ba2 + (s->stnS_.s12() + s12old) * z2_con) * s->getSubZoneVolume();

s->working_[10] += (Mekd_[10] * ba2 + (s->stnS_.s13() + s13old) * z2_con) * s->getSubZoneVolume();

s->working_[11] += (Mekd_[11] * ba2 + (s->stnS_.s23() + s23old) * z2_con) * s->getSubZoneVolume();

//--- update stored Kelvin-strains and plastic strain ---

if (s->sub_zone_ == s->total_sub_zones_ - 1) {//这行代码检查是否在最后一个子区域内,如果是,则执行后续的更新操作

Double Aux = 1. / s->getZoneVolume();//Aux变量是区域体积的倒数

if (s->overlay_ == 2) Aux *= 0.5;//如果overlay_等于2,则Aux乘以0.5.

Mekd_[0] = s->working_[0] * Aux;

Mekd_[1] = s->working_[1] * Aux;

Mekd_[2] = s->working_[2] * Aux;

Mekd_[3] = s->working_[3] * Aux;

Mekd_[4] = s->working_[4] * Aux;

Mekd_[5] = s->working_[5] * Aux;

Mekd_[6] = s->working_[6] * Aux;

Mekd_[7] = s->working_[7] * Aux;

Mekd_[8] = s->working_[8] * Aux;

Mekd_[9] = s->working_[9] * Aux;

Mekd_[10] = s->working_[10] * Aux;

Mekd_[11] = s->working_[11] * Aux;

if (canFail()) {

sHP_ += s->working_[Dqs] * Aux;

tHP_ += s->working_[Dqt] * Aux;

}

}

// excerpt-run-end

}

} // namespace models

// EOF这个是我的本构,不管怎么跑都会进入加速蠕变阶段,下面是burgers-mohr的你对比来看看#include "modelcvisc.h"

#include "base/src/version.h"

namespace models {

ModelCVisc::ModelCVisc() : ModelBurger(),

cohesion_(0.0),friction_(0.0),dilation_(0.0),tension_(0.0),

sHP_(0.0),tHP_(0.0),nph_(0.0),csn_(0.0),rc_(0.0),nps_(0.0) {

}

UInt ModelCVisc::getMinorVersion() const{

return version::update;

}

String ModelCVisc::getProperties(void) const {

return ModelBurger::getProperties() +

L",cohesion,friction,dilation,tension,strain-shear-plastic,strain-tensile-plastic -strain-tension-plastic";

}

String ModelCVisc::getStates(void) const {

return L"shear-n,tension-n,shear-p,tension-p";

}

Variant ModelCVisc::getProperty(UInt index) const {

if (index <= 11)

return ModelBurger::getProperty(index);

else {

switch (index) {

case 12: return cohesion_;

case 13: return friction_;

case 14: return dilation_;

case 15: return tension_;

case 16: return sHP_;

case 17: return tHP_;

}

}

return(0.0);

}

void ModelCVisc::setProperty(UInt index, const Variant &p,UInt restoreVersion) {

if (index <= 11)

ModelBurger::setProperty(index,p,restoreVersion);

else {

switch (index) {

case 12: cohesion_ = p.toDouble(); break;

case 13: friction_ = p.toDouble(); break;

case 14: dilation_ = p.toDouble(); break;

case 15: tension_ = p.toDouble(); break;

case 16: sHP_ = p.toDouble(); break;

case 17: tHP_ = p.toDouble(); break;

}

}

}

void ModelCVisc::copy(const ConstitutiveModel *m) {

const ModelCVisc *vm = dynamic_cast<const ModelCVisc *>(m);

if (!vm) throw std::runtime_error("Internal error: constitutive model dynamic cast failed.");

ModelBurger::copy(m);

cohesion_ = vm->cohesion_;

friction_ = vm->friction_;

dilation_ = vm->dilation_;

tension_ = vm->tension_;

sHP_ = vm->sHP_;

tHP_ = vm->tHP_;

}

void ModelCVisc::initialize(UByte d,State *s) {

ModelBurger::initialize(d, s);

Double rsin = std::sin(friction_ * degrad);

nph_ = (1.0 + rsin) / (1.0 - rsin);

csn_ = 2.0 * cohesion_ * sqrt(nph_);

if (friction_) {

Double apex = cohesion_ / std::tan(friction_ * degrad);

tension_ = std::min(tension_,apex);

}

rsin = std::sin(dilation_ * degrad);

nps_ = (1.0 + rsin) / (1.0 - rsin);

rc_ = std::sqrt(1.0 + nph_*nph_);

}

static const UInt Dqs = 6;

static const UInt Dqt = 7;

void ModelCVisc::run(UByte d,State *s) {

ConstitutiveModel::run(d,s);

if (s->state_ & shear_now) s->state_ |= shear_past;

s->state_ &= ~shear_now;

if (s->state_ & tension_now) s->state_ |= tension_past;

s->state_ &= ~tension_now;

UInt iPlas = 0;

Double tempk=0, tempm=0;

Double dCrtdel = (s->isCreep() ? s->getTimeStep() : 0.0);

Double dSubZoneVolume = s->getSubZoneVolume();

if (!s->sub_zone_) {

s->working_[0] = 0.0;

s->working_[1] = 0.0;

s->working_[2] = 0.0;

s->working_[3] = 0.0;

s->working_[4] = 0.0;

s->working_[5] = 0.0;

s->working_[Dqs] =0.0;

s->working_[Dqt] =0.0;

}

if(Kviscosity_ <= 0.0) tempk = 0.0;

else tempk = 1.0 / Kviscosity_ ;

//

if (Mviscosity_ <= 0.0) tempm = 0.0;

else tempm = 1.0 / Mviscosity_ ;

Double temp = 0.5 * Kshear_ * dCrtdel * tempk;

Double a_con = 1.0 + temp;

Double b_con = 1.0 - temp;

Double ba = b_con / a_con;

Double bal = ba - 1.0;

temp = (tempm + tempk / a_con) * dCrtdel * 0.25 ;

Double temp1 = 0.5 / Mshear_;

Double x_con = temp1 + temp;

Double y_con = temp1 - temp;

Double z_con = dCrtdel * tempk / (4.0 * a_con);

Double c1dxc = 1.0 / x_con;

//;--- partition strains ---

Double dev = s->stnE_.s11() + s->stnE_.s22() + s->stnE_.s33() ;

Double dev3 = d1d3 * dev;

Double de11d = s->stnE_.s11() - dev3;

Double de22d = s->stnE_.s22() - dev3;

Double de33d = s->stnE_.s33() - dev3;

//;--- partition stresses---

Double s0 = d1d3 * (s->stnS_.s11() + s->stnS_.s22() + s->stnS_.s33());

Double s11d = s->stnS_.s11() - s0;

Double s22d = s->stnS_.s22() - s0;

Double s33d = s->stnS_.s33() - s0;

//;--- remember old stresses ---

Double s11old = s11d;

Double s22old = s22d;

Double s33old = s33d;

Double s12old = s->stnS_.s12();

Double s13old = s->stnS_.s13();

Double s23old = s->stnS_.s23();

//;--- new trial deviator stresses assuming viscoelastic increments ---

s11d = (de11d + s11d * y_con - Mekd_[0] * bal) * c1dxc ;

s22d = (de22d + s22d * y_con - Mekd_[1]* bal) * c1dxc ;

s33d = (de33d + s33d * y_con - Mekd_[2]* bal) * c1dxc ;

Double s12i = (s->stnE_.s12() + s->stnS_.s12() * y_con - Mekd_[3] * bal) * c1dxc ;

Double s13i = (s->stnE_.s13() + s->stnS_.s13() * y_con - Mekd_[4] * bal) * c1dxc ;

Double s23i = (s->stnE_.s23() + s->stnS_.s23() * y_con - Mekd_[5] * bal) * c1dxc ;

//;--- new trial isotropic stress assuming elastic increment ---

s0 += bulk_ * dev;

Double s11i = s11d + s0;

Double s22i = s22d + s0;

Double s33i = s33d + s0;

//; --- trial stresses ---

s->stnS_.rs11() = s11i;

s->stnS_.rs22() = s22i;

s->stnS_.rs33() = s33i;

s->stnS_.rs12() = s12i;

s->stnS_.rs13() = s13i;

s->stnS_.rs23() = s23i;

if (canFail()) {

SymTensorInfo info;

DVect3 prin = s->stnS_.getEigenInfo(&info);

Double e1_ = bulk_ + d2d3*c1dxc;

Double e2_ = bulk_ - d1d3*c1dxc;

Double ra = e1_ - nps_*e2_;

Double rb = e2_ - nps_*e1_;

Double rd = ra - rb*nph_;

Double sc1_ = ra / rd;

Double sc3_ = rb / rd;

Double sc2_ = e2_*(1.0 - nps_)/rd;

Double e21_ = e2_/e1_;

Double sf1_ = 1.0/rd;

Double sf3_ = - nps_/rd;

Double fs = - prin.x() + nph_ * prin.z() - csn_;

Double fsd = fs / rc_;

Double ftz = prin.z() - tension_;

Double fty = prin.y() - tension_;

Double ftx = prin.x() - tension_;

if (fsd > 0.0 && fsd >= ftz) {

iPlas = 1;

s->state_ |= shear_now;

prin.rx() += fs * sc1_;

prin.ry() += fs * sc2_;

prin.rz() += fs * sc3_;

}

else if (ftz > 0.0 && ftz >= fsd) {

s->state_ |= tension_now;

if (ftx > 0.0) {

iPlas = 4;

prin.rx() = tension_;

prin.ry() = tension_;

prin.rz() = tension_;

} else if (fty > 0.0) {

iPlas = 3;

prin.rx() -= (fty + ftz) * e2_/(e1_+e2_);

prin.ry() = tension_;

prin.rz() = tension_;

} else {

iPlas = 2;

Double tco = ftz * e21_;

prin.rx() -= tco;

prin.ry() -= tco;

prin.rz() = tension_;

}

}

if (friction_ > 0.0) {

Double apex = cohesion_ / tan(friction_*degrad);

if (prin.x()>=apex || prin.y()>=apex || prin.z()>=apex) {

iPlas = 4;

s->state_ |= tension_now;

prin.rx() = apex;

prin.ry() = apex;

prin.rz() = apex;

}

}

if (iPlas) {

s->stnS_ = info.resolve(prin);

if (iPlas == 1) {

Double dDe1p = fs * sf1_;

Double dDe3p = fs * sf3_;

Double dDepa = d1d3 * (dDe1p + dDe3p);

dDe1p -= dDepa;

dDe3p -= dDepa;

s->working_[Dqs] += sqrt(0.5 * (dDe1p*dDe1p+dDepa*dDepa+dDe3p*dDe3p)) * dSubZoneVolume;

}

if (iPlas == 2) {

Double dAux = ftz / e1_;

s->working_[Dqt] += dAux * dSubZoneVolume;

}

if (iPlas == 3) {

Double dAux = (ftz+fty) / (e1_+e2_);

s->working_[Dqt] += dAux * dSubZoneVolume;

}

if (iPlas == 4) {

Double dAux = (ftz+fty+ftx) / bulk_;

s->working_[Dqt] += dAux * dSubZoneVolume;

}

}

}

//--- sub-zone contribution to Kelvin-strains ---

s0 = d1d3 * (s->stnS_.s11() + s->stnS_.s22() + s->stnS_.s33());

s->working_[0] += (Mekd_[0] * ba + (s->stnS_.s11() - s0 + s11old) * z_con) * s->getSubZoneVolume();

s->working_[1] += (Mekd_[1] * ba + (s->stnS_.s22() - s0 + s22old) * z_con) * s->getSubZoneVolume();

s->working_[2] += (Mekd_[2] * ba + (s->stnS_.s33() - s0 + s33old) * z_con) * s->getSubZoneVolume();

s->working_[3] += (Mekd_[3] * ba + (s->stnS_.s12() + s12old) * z_con) * s->getSubZoneVolume();

s->working_[4] += (Mekd_[4] * ba + (s->stnS_.s13() + s13old) * z_con) * s->getSubZoneVolume();

s->working_[5] += (Mekd_[5] * ba + (s->stnS_.s23() + s23old) * z_con) * s->getSubZoneVolume();

//--- update stored Kelvin-strains and plastic strain ---

if (s->sub_zone_ == s->total_sub_zones_-1) {

Double Aux = 1./s->getZoneVolume();

if (s->overlay_==2) Aux *= 0.5;

Mekd_[0]= s->working_[0] * Aux;

Mekd_[1]= s->working_[1] * Aux;

Mekd_[2]= s->working_[2] * Aux;

Mekd_[3]= s->working_[3] * Aux;

Mekd_[4]= s->working_[4] * Aux;

Mekd_[5]= s->working_[5] * Aux;

if (canFail()) {

sHP_ += s->working_[Dqs]*Aux;

tHP_ += s->working_[Dqt]*Aux;

}

}

}

}

// EOF

最新发布

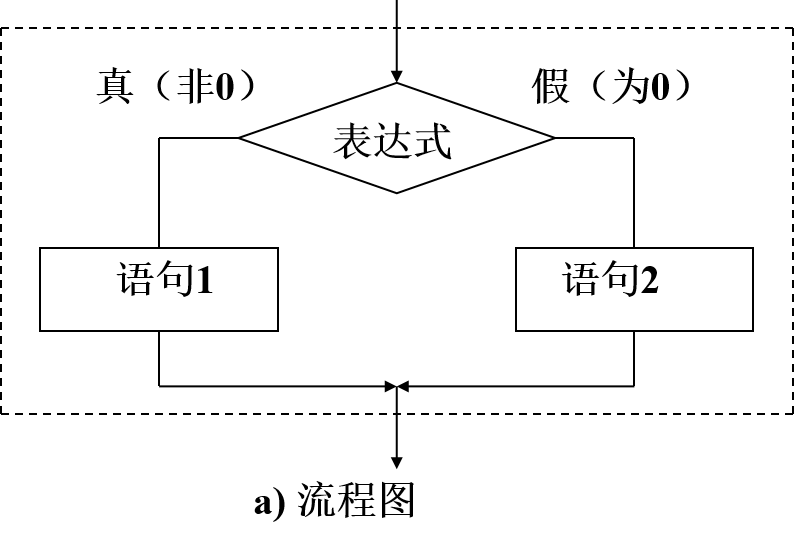

本文档展示了如何使用C语言中的if-else结构,通过输入的两个整数进行比较,找出最大值和最小值,并根据结果输出相应的消息。教程包括输入格式、输出格式以及示例代码的解析。

本文档展示了如何使用C语言中的if-else结构,通过输入的两个整数进行比较,找出最大值和最小值,并根据结果输出相应的消息。教程包括输入格式、输出格式以及示例代码的解析。

6504

6504

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?