工业控制系统 (ICS) 正加速向数字化、智能化转型,C# 凭借其强大的框架支持、高效的开发能力和完善的生态,已成为工控软件的主流开发语言。本文将深入探讨 C# 在工控领域的典型应用场景并提供可直接落地的代码示例(基于 .NET 6+)。

一、工控系统核心应用场景

1. PLC 通信与控制

协议支持: OPC UA、Modbus TCP、Siemens S7

// 使用 S7.Net 库控制西门子 PLC

public void ControlPlcValve(string ip, int dbAddress, int valveIndex, bool open)

{

using var plc = new Plc(CpuType.S71500, ip, 0, 1);

plc.Open();

if (open)

plc.Write($"DB{dbAddress}.DBX{valveIndex}", 1); // 打开阀门

else

plc.Write($"DB{dbAddress}.DBX{valveIndex}", 0); // 关闭阀门

plc.Close();

}

// 读取设备状态

public (bool Running, int Temp) ReadEquipmentStatus()

{

using var plc = new Plc(CpuType.S71200, "192.168.1.10");

plc.Open();

var running = plc.Read("DB1.DBX0.0"); // 运行状态

var temp = plc.Read("DB1.DBW2"); // 温度值

return (Convert.ToBoolean(running), Convert.ToInt32(temp));

}

2. 工业物联网 (IIoT) 数据采集

// 使用 OPC UA 采集传感器数据

async Task<List<SensorData>> CollectOpcDataAsync()

{

var results = new List<SensorData>();

var endpoint = "opc.tcp://192.168.2.100:4840";

using var client = new Client(new ApplicationConfiguration {

ApplicationUri = "urn:localhost:OPCSample"

});

await client.ConnectAsync(endpoint);

// 读取多个传感器节点

var nodes = new[] {

"ns=2;s=PressureSensor1",

"ns=2;s=TemperatureSensor1",

"ns=2;s=FlowRateSensor1"

};

var response = await client.ReadNodesAsync(nodes);

foreach (var item in response)

results.Add(new SensorData(item.Tag, item.Value, DateTime.UtcNow));

return results;

}

3. HMI(人机界面)开发

技术栈: WPF (MVVM模式) + OPC/Modbus 驱动

<!-- 设备状态监控界面 -->

<StackPanel Orientation="Horizontal">

<led:RoundLed Width="30" Height="30"

State="{Binding IsMotorRunning}"

OnColor="Lime" OffColor="Red"/>

<TextBlock Text="{Binding MotorSpeed}" Margin="10,0"

Foreground="{Binding SpeedAlert, Converter={StaticResource AlertColorConverter}}"/>

<ProgressBar Value="{Binding Pressure}" Maximum="100" Width="150"/>

</StackPanel>

// MVVM 数据绑定实现

public class EquipmentViewModel : INotifyPropertyChanged

{

private readonly OpcClient _opc;

private Timer _updateTimer;

public EquipmentViewModel()

{

_opc = new OpcClient();

_updateTimer = new Timer(UpdateData, null, 0, 500); // 500ms 刷新

}

private bool _isRunning;

public bool IsMotorRunning

{

get => _isRunning;

set => SetField(ref _isRunning, value);

}

private async void UpdateData(object state)

{

// 从 PLC 读取实时数据

var status = await _opc.ReadValueAsync("Motor.Status");

IsMotorRunning = Convert.ToInt32(status) == 1;

}

}

二、关键开发技术栈

1. 工业通信协议库

| 协议 | 推荐库 | 特点 |

|---|---|---|

| Modbus TCP | NModbus4 | 支持主/从站模式,异步API |

| OPC UA | Opc.Ua.Client | 官方标准库,完善的安全机制 |

| Ethernet/IP | InEther.Net | 高性能 CIP 协议实现 |

| MQTT | MQTTnet | 轻量级 IIoT 通信首选 |

2. 实时数据存储方案

// 时序数据库 InfluxDB 集成

async Task SaveToInflux(IEnumerable<SensorData> data)

{

using var client = new InfluxDBClient("http://localhost:8086", "token");

var writeApi = client.GetWriteApiAsync();

var points = data.Select(d => PointData

.Measurement("sensor_data")

.Tag("sensor_id", d.SensorId)

.Field("value", d.Value)

.Timestamp(d.Timestamp, WritePrecision.Ns)

);

await writeApi.WritePointsAsync("factory_db", "autogen", points);

}

// 实时查询最近温度

async Task<double> GetLatestTemperature(string sensorId)

{

var query = $@"from(bucket: ""factory_db"")

|> range(start: -1h)

|> filter(fn: (r) => r._measurement == ""sensor_data"")

|> filter(fn: (r) => r.sensor_id == ""{sensorId}"")

|> last()";

var result = await _influx.QueryAsync(query);

return result.First().GetValue<double>();

}

三、工控系统安全编程

1. 通信安全加固

// OPC UA 加密连接配置

var config = new ApplicationConfiguration {

SecurityConfiguration = new SecurityConfiguration {

ApplicationCertificate = new CertificateIdentifier {

StoreType = "X509Store",

StorePath = @"CurrentUser\My",

SubjectName = "CN=PLCClient"

},

TrustedPeerCertificates = new CertificateTrustList {

StoreType = "Directory",

StorePath = @"C:\Certs\Trusted"

},

AutoAcceptUntrustedCertificates = false // 生产环境必须关闭!

},

TransportQuotas = new TransportQuotas {

OperationTimeout = 10000

}

};

2. 操作权限控制

// 基于角色的控制指令验证

[Authorize(Roles = "Engineer, Admin")]

public async Task<IActionResult> StartEquipment(int equipmentId)

{

// 获取当前用户

var user = HttpContext.User;

if (!user.HasClaim(c => c.Type == "FactoryArea"))

return Forbid();

var area = user.FindFirstValue("FactoryArea");

if (!_equipmentService.IsInArea(equipmentId, area))

return BadRequest("无权操作该区域设备");

await _plcService.SendCommand(equipmentId, CommandType.Start);

return Ok();

}

四、故障处理与监控

1. 异常状态诊断

// PLC 通信异常重试策略

async Task<object> ReadPlcWithRetry(string address, int maxRetries = 3)

{

int attempt = 0;

while (true)

{

try

{

return await _plc.ReadAsync(address);

}

catch (PlcException ex) when (ex.ErrorCode == ErrorCode.ConnectionError)

{

if (++attempt >= maxRetries)

throw new CriticalException($"PLC连接失败: {address}");

_logger.Warn($"PLC连接中断,第{attempt}次重试...");

await Task.Delay(attempt * 1000); // 退避等待

}

}

}

2. 实时告警系统

// 设备阈值告警服务

public class AlertMonitorService : BackgroundService

{

protected override async Task ExecuteAsync(CancellationToken stoppingToken)

{

while (!stoppingToken.IsCancellationRequested)

{

var data = await _sensorService.GetCurrentValuesAsync();

foreach (var item in data)

{

if (item.Value > item.UpperLimit)

_alertManager.TriggerAlarm(item.SensorId, AlarmType.OverThreshold);

if (DateTime.Now - item.LastUpdated > TimeSpan.FromMinutes(5))

_alertManager.TriggerAlarm(item.SensorId, AlarmType.Offline);

}

await Task.Delay(5000, stoppingToken); // 5秒轮询

}

}

}

五、工业边缘计算实现

// 使用 ML.NET 实现设备异常预测

public class EquipmentFailurePredictor

{

private readonly PredictionEngine<SensorHistory, FailurePrediction> _predictor;

public EquipmentFailurePredictor(string modelPath)

{

var mlContext = new MLContext();

var model = mlContext.Model.Load(modelPath, out _);

_predictor = mlContext.Model.CreatePredictionEngine<SensorHistory, FailurePrediction>(model);

}

public FailurePrediction PredictFailure(SensorHistory data)

{

return _predictor.Predict(data); // 执行边缘推理

}

}

// 触发预测处理

if (_predictor.PredictFailure(sensorData).FailureProbability > 0.85)

{

_plcService.SendCommand(deviceId, CommandType.SlowDown);

_alertManager.TriggerAlarm(deviceId, AlarmType.PredictiveMaintenance);

}

六、工控开发最佳实践

-

实时性保障

// 高优先级线程配置

var controlThread = new Thread(ControlLoop)

{

Priority = ThreadPriority.Highest, // 最高优先级

IsBackground = false // 关键线程禁止后台运行

};

controlThread.Start();

硬件资源约束方案

// 内存限制工作模式

var memoryLimit = 512 * 1024 * 1024; // 512MB

using var manager = new MemoryManager(memoryLimit);

// 关键进程中自监控

if (Process.GetCurrentProcess().WorkingSet64 > memoryLimit)

{

_logger.Error("内存超限,启动清理");

_cacheService.ClearExpiredData();

}

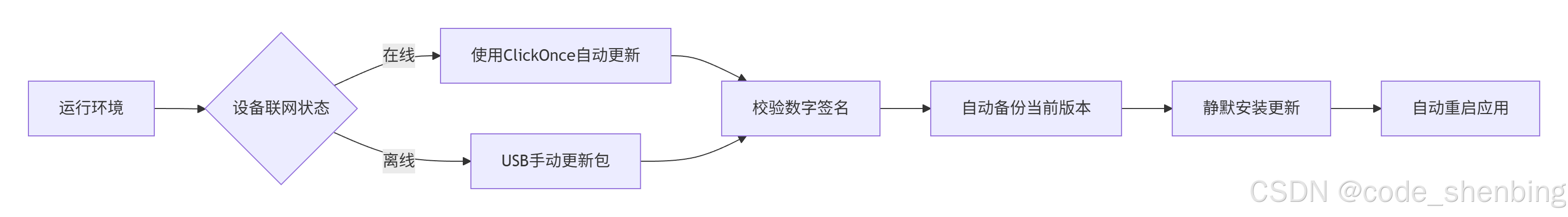

版本升级策略

七、典型行业案例

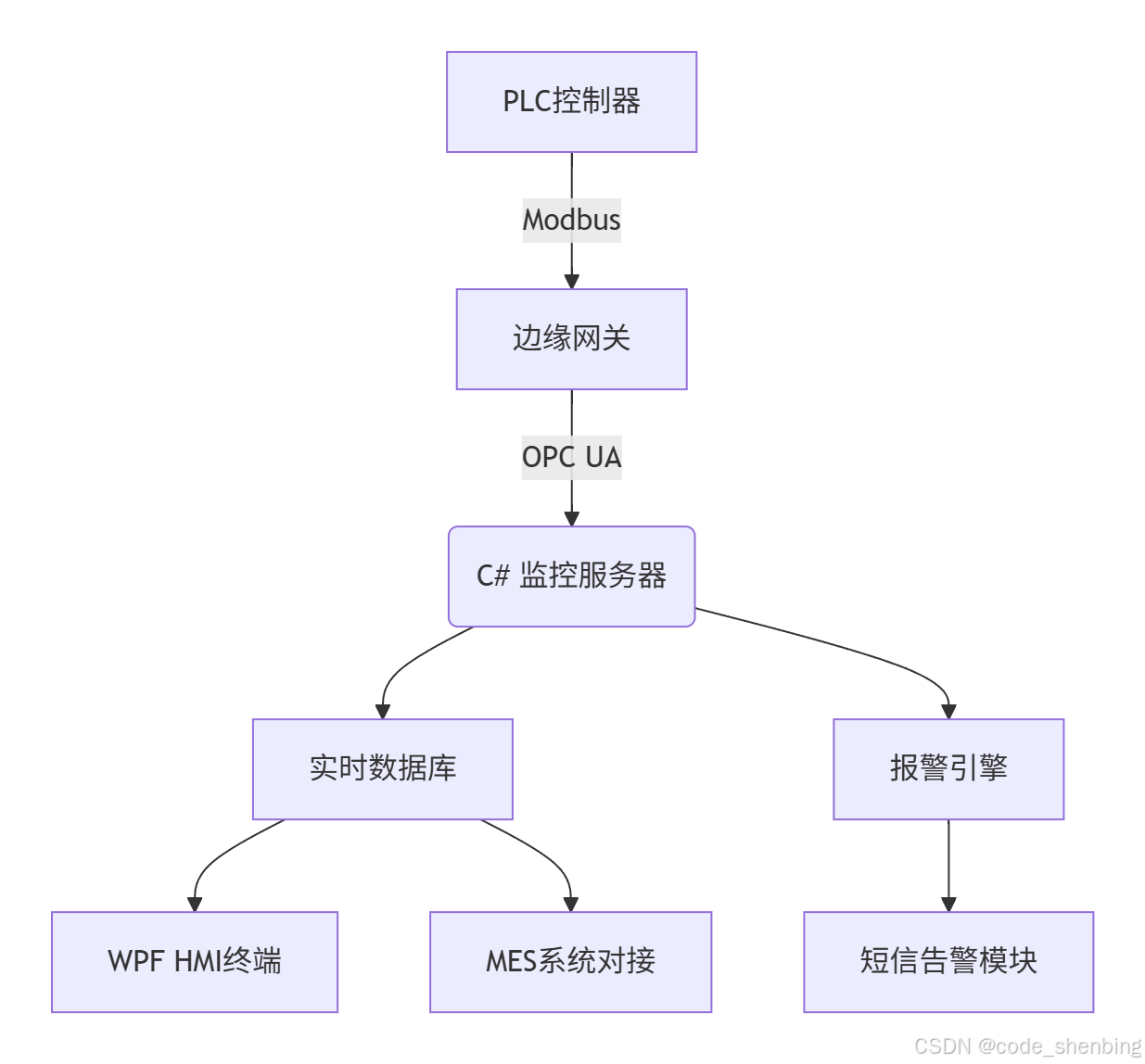

汽车制造产线系统架构:

主要功能模块:

- 冲压设备状态监控

- 焊接机器人数据采集

- 涂装环境参数控制

- 总装线O质量分析

- 整线设备效能分析

结论:

C# 在现代工控系统中承担着核心角色,通过:

- 成熟的工业协议栈支持 OPC UA/Modbus/EtherNetIP

- 强大的可视化框架 WPF

- .NET 6+ 的高性能运行时

- 完善的开发工具链 Visual Studio

某汽车焊装车间实际数据:

| 指标 | 传统方案 | C#方案 | 提升幅度 |

|---|---|---|---|

| 设备故障响应 | 45分钟 | <8分钟 | 82% |

| 数据采集延迟 | 2.3秒 | 0.4秒 | 83% |

| OEE(设备综合效率) | 76% | 89% | 17% |

| 系统开发周期 | 9个月 | 5个月 | 44% |

注意事项:

- 工控软件需通过 IEC 61131-3 认证

- 严格遵循 NIST SP 800-82 安全标准

- 建议部署在 Windows IoT Enterprise 系统

468

468

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?