根据上一篇博客描述,数码管驱动在实际应用此输出占用的管脚过多,所以为了节省FPGA的管脚,需要将输出信号并转串后(FPGA只需要输出3个管脚),再利用串转并芯片(比如74HC595)连接数码管去显示需要输出的字符。如下功能示意图:

从上图可以看到FPGA管脚从16个节省到3个。

74HC595芯片是一个8位串行移位寄存器,下图是一个4位的串行移位寄存器。

每个时钟周期Q端口的值都会发生变化

LATCH时钟不出现上升沿,OUTPUT端口数据就不发生变化

那么8位串行移位寄存器如下:

上图可以用Verilog实现,那么就可以制作成对应的芯片(74HC595)如下(芯片手册内容):

如果需要16位的移位寄存器呢:

只需要将前一芯片的输出QH-连接到下一芯片的D1就实现了16位移位寄存器

下图是电路图:

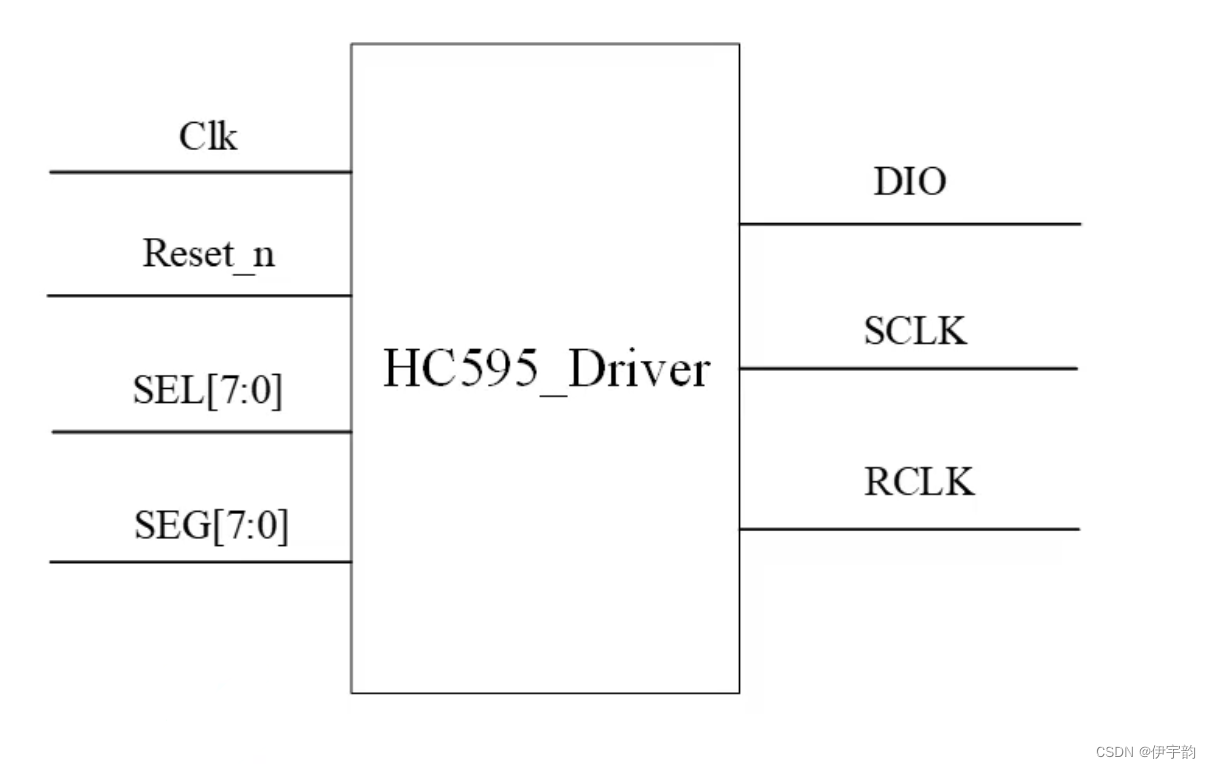

那么我们的任务就是:如何将上一篇博客的SEL输出和SEG输出两个8位共16位的值通过DIO,RCLK,SCLK传到2片级联的74HC595。

实现一个驱动逻辑,通过这3根信号线能正确的给74HC595位数据。

即需要在FPGA中实现一下逻辑功能,如下图:

并串转换逻辑。

下图是芯片输入输出时序图:

时序逻辑

代码编写:

先看一下期望实现波形图:

代码如下:

module HC595_driver(

Clk,

Reset_n,

SEG,

SEL,

DIO,

SRCLK,

RCLK

);

input Clk;

input Reset_n;

input [7:0]SEG;

input [7:0]SEL;

output reg DIO;

output reg SRCLK;

output reg RCLK;

parameter CLOCK_FREQ = 50_000_000;

parameter SRCLK_FREQ = 12_500_000;

parameter MCNT = CLOCK_FREQ/(SRCLK_FREQ * 2) -1;

//SRCLK 2V时5MHZ 5V是25MHZ 那么3.3V时就大致取12.5MHZ 40ns

//主频假设最高1GHZ 最低1hz [29:0]div_count 编译器会根据实际使用确定实际尾位宽

reg [29:0]div_count;

reg [4:0]cnt;

always@(posedge Clk or negedge Reset_n)

if(!Reset_n)

div_count <= 0;

else if (div_count == MCNT)

div_count <= 0;

else

div_count <= div_count +1'd1;

always@(posedge Clk or negedge Reset_n)

if(!Reset_n)

cnt <= 0;

else if (div_count == MCNT)

cnt <= cnt + 1'd1;

always@(posedge Clk or negedge Reset_n)

if(!Reset_n)begin

DIO = 1'd0; SRCLK <= 1'd0; RCLK <= 1'd0;

end

else begin

case(cnt)

0:begin DIO = SEG[7]; SRCLK <= 1'd0; RCLK <= 1'd1;end

1:begin SRCLK <= 1'd1; RCLK <= 1'd0; end

2:begin DIO = SEG[6]; SRCLK <= 1'd0; end

3:begin SRCLK <= 1'd1; end

4:begin DIO = SEG[5]; SRCLK <= 1'd0; end

5:begin SRCLK <= 1'd1; end

6:begin DIO = SEG[4]; SRCLK <= 1'd0; end

7:begin SRCLK <= 1'd1; end

8:begin DIO = SEG[3]; SRCLK <= 1'd0; end

9:begin SRCLK <= 1'd1; end

10:begin DIO = SEG[2]; SRCLK <= 1'd0; end

11:begin SRCLK <= 1'd1; end

12:begin DIO = SEG[1]; SRCLK <= 1'd0; end

13:begin SRCLK <= 1'd1; end

14:begin DIO = SEG[0]; SRCLK <= 1'd0; end

15:begin SRCLK <= 1'd1; end

16:begin DIO = SEL[7]; SRCLK <= 1'd0; end

17:begin SRCLK <= 1'd1; end

18:begin DIO = SEL[6]; SRCLK <= 1'd0; end

19:begin SRCLK <= 1'd1; end

20:begin DIO = SEL[5]; SRCLK <= 1'd0; end

21:begin SRCLK <= 1'd1; end

22:begin DIO = SEL[4]; SRCLK <= 1'd0; end

23:begin SRCLK <= 1'd1; end

24:begin DIO = SEL[3]; SRCLK <= 1'd0; end

25:begin SRCLK <= 1'd1; end

26:begin DIO = SEL[2]; SRCLK <= 1'd0; end

27:begin SRCLK <= 1'd1; end

28:begin DIO = SEL[1]; SRCLK <= 1'd0; end

29:begin SRCLK <= 1'd1; end

30:begin DIO = SEL[0]; SRCLK <= 1'd0; end

31:begin SRCLK <= 1'd1; end

endcase

end

endmodule

编写testbench测试代码:

`timescale 1ns / 1ps

module HC595_driver_tb();

reg Clk;

reg Reset_n;

reg [7:0]SEG;

reg [7:0]SEL;

wire DIO;

wire SRCLK;

wire RCLK;

HC595_driver HC595_driver1(

.Clk(Clk),

.Reset_n(Reset_n),

.SEG(SEG),

.SEL(SEL),

.DIO(DIO),

.SRCLK(SRCLK),

.RCLK(RCLK)

);

initial Clk = 1;

always #10 Clk = ~Clk;

initial begin

Reset_n = 0;

SEL = 8'b0000_0001;

SEG = 8'b0101_0101;

#201

Reset_n = 1;

#5000;

SEL = 8'b0000_0010;

SEG = 8'b1010_1010;

#5000;

SEL = 8'b1010_0101;

SEG = 8'b0000_1101;

#5000;

$stop;

end

endmodule

波形图如下:

至此我们完成了74HC595芯片输入逻辑驱动设计

接下来我们将上一篇博客数码管驱动 与上面所写的74HC595芯片驱动连接起来;

因为数码管显示输入为32位数据,一般开发板无法提供这么多的引脚,所以使用2个拨码开关,设置4组数据作为测试;详情看代码:

module digitial_tube_hc595(

Clk,

Reset_n,

SW,

DIO,

SRCLK,

RCLK

);

input Clk;

input Reset_n;

input [1:0]SW;

output DIO;

output SRCLK;

output RCLK;

wire [7:0]SEL;

wire [7:0]SEG;

reg[31:0]Disp_Data;

digitial_tube_0 digitial_tube_0(

.Clk(Clk),

.Reset_n(Reset_n),

.Disp_Data(Disp_Data),

.SEL(SEL),

.SEG(SEG)

);

HC595_driver HC595_driver1(

.Clk(Clk),

.Reset_n(Reset_n),

.SEG(SEG),

.SEL(SEL),

.DIO(DIO),

.SRCLK(SRCLK),

.RCLK(RCLK)

);

always@(*)

case(SW)

0:Disp_Data <= 32'h01234567;

1:Disp_Data <= 32'h89abcdef;

2:Disp_Data <= 32'h02468ace;

3:Disp_Data <= 32'h13579bdf;

endcase

endmodule

至此,整个数码管驱动逻辑到此结束!

本文介绍了如何通过FPGA的管脚优化,利用74HC595串行移位寄存器将16位数码管的输出信号并转串,仅需3个管脚,详细解释了Verilog代码实现和时序逻辑设计,以及如何与数码管驱动结合使用。

本文介绍了如何通过FPGA的管脚优化,利用74HC595串行移位寄存器将16位数码管的输出信号并转串,仅需3个管脚,详细解释了Verilog代码实现和时序逻辑设计,以及如何与数码管驱动结合使用。

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?