IMMT Final Report on Additive and Subtractive Manufacturing

Abstract

In the past half-century, traditional manufacturing processes such as mechanical processing and injection molding with high quality, low cost, and high speed have been regarded as the industrial standard for mass production. At the time, additive manufacturing (also known as 3D printing) was only useful in the context of rapid prototyping and small-batch production operations.

Nowadays, with the continuous shortening of product life cycle and the ever-increasing demand for personalized products, companies are beginning to face great pressure on the time to market and cost of products, and the efficiency of traditional manufacturing technology is no longer adequate. However, in recent years, additive manufacturing technology has made rapid progress in the field of equipment and materials. It is not surprising that the rapidly taking off additive manufacturing technology has surpassed the manufacturing industry and entered the medical and other markets. From nanoscale metal structures and food to human tissues and organs, buildings, and even the entire city may be printed in the future-all kinds of dazzling things can be 3D printed, showing endless possibilities.

This article mainly introduces the definition of additive manufacturing and subtractive manufacturing, related technologies, industry applications, and future development trends, aiming to have a detailed and in-depth understanding of these two technology groups.

1. Introduction

1.1 Definition of Additive Manufacturing and Subtractive Manufacturing

Additive manufacturing technology refers to a scientific and technological system that directly manufactures parts driven by 3d data of parts based on discrete-stacking principle. Based on different classification principles and ways of understanding, additive manufacturing technology is also called rapid prototyping, rapid manufacturing, 3D printing and so on. [1]

Subtractive Manufacturing is conceptually relative to “additive manufacturing”. It clamps and fixes the raw material on the equipment, and cuts the excess material layer on the blank or workpiece into chips by cutting tools, so that the workpiece can obtain the specified geometric shape, size and surface quality. [2]

1.2 Classifications

Academician Guan Qiao proposed the concepts of “broad sense” and “narrow sense” additive manufacturing. The “narrow sense” additive manufacturing refers to the technical system of combining different energy sources with CAD/CAM technology and layering and accumulating materials; and “broad sense” Additive manufacturing is a large-scale technology group with the basic feature of material accumulation and the goal of directly manufacturing parts. If classified according to the type and method of processing materials, it can be divided into metal forming, non-metal forming, and biological material forming.

Subtractive Manufacturing can be divided into two categories: cutting methods with fixed blade shape and number of blades include turning, drilling, boring, milling, planing, broaching and sawing; cutting methods with unfixed blade shape and number of blades using abrasive tools or abrasives include grinding, honing, polishing, etc.

2. Related Technologies

2.1 Related Technologies for Additive Manufacturing

2.1.1 Stereo Lithography Apparatus (SLA)

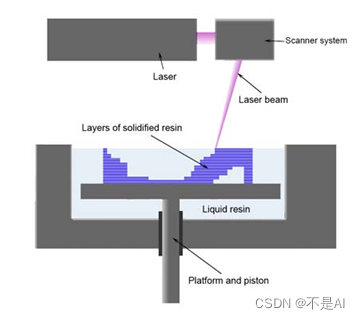

Stereo lithography technology uses a computer to control the laser beam, and through the design data provided by the CAD system, the beam is used to solidify the liquid photosensitive resin layer by layer. It combines the horizontal movement of the laser beam and the vertical movement of the platform to create three-dimensional objects. [3]

Figure 1. Stereo Lithography Apparatus (SLA)

2.1.2 Selective Laser Sintering (SLS)

Selective Laser Sintering uses infrared lasers as energy sources, and most of the modeling materials used are powder materials. During processing, the powder is first preheated to a temperature slightly lower than its melting point, and then the powder is flattened under the action of a flattening stick; the laser beam is selectively sintered according to the information of the layered cross section under computer control, and one layer

最低0.47元/天 解锁文章

最低0.47元/天 解锁文章

1952

1952

被折叠的 条评论

为什么被折叠?

被折叠的 条评论

为什么被折叠?